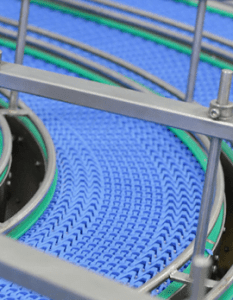

Conveyor belt brushes are a vital component in the manufacturing sector, engineered to cleanse conveyor belts and eliminate debris, dirt and other contaminants that may impact the efficiency and quality of the production process. These brushes are typically fabricated from hard-wearing materials such as nylon, polypropylene or steel, and are offered in various configurations to accommodate different conveyor belt systems. The brushes are fitted along the conveyor belt to effectively clean the surface and ensure smooth operation of the production line.

Conveyor belt brushes fulfil a critical function in maintaining the cleanliness of conveyor belts, preventing product contamination and enhancing overall manufacturing efficiency. By effectively removing debris and contaminants, these brushes help to improve product quality and consistency, reduce maintenance and downtime, and provide health and safety benefits for workers. Furthermore, the utilisation of conveyor belt brushes contributes to environmental sustainability by reducing waste and improving energy efficiency.

In summary, conveyor belt brushes represent a valuable investment for manufacturing facilities seeking to enhance their production processes and achieve cost savings over time.

Summary

- Conveyor belt brushes are essential components in the manufacturing industry for cleaning and maintaining conveyor belts.

- The use of conveyor belt brushes can lead to increased efficiency in manufacturing processes by reducing downtime and improving overall productivity.

- Conveyor belt brushes contribute to improved product quality and consistency by ensuring that the conveyor belts are clean and free from debris.

- The use of conveyor belt brushes can result in a reduction in maintenance and downtime, leading to cost savings and improved operational efficiency.

- Conveyor belt brushes also provide health and safety benefits for workers by reducing the risk of accidents and injuries associated with manual cleaning methods.

Increased Efficiency in Manufacturing Processes

Improved Productivity and Throughput

This ultimately leads to improved productivity and throughput, allowing manufacturing facilities to meet production targets and deadlines more effectively. Furthermore, conveyor belt brushes help to reduce the need for manual cleaning of conveyor belts, saving time and labour costs. By automating the cleaning process, manufacturing facilities can allocate resources more efficiently and focus on other critical tasks.

Enhanced Working Environment

This not only increases overall efficiency but also improves the working environment for employees by reducing the need for manual labour in potentially hazardous conditions.

Extended Conveyor Belt Lifespan

In addition, the use of conveyor belt brushes can also extend the lifespan of conveyor belts by preventing excessive wear and tear caused by debris and contaminants, further contributing to increased efficiency in manufacturing processes.

Improved Product Quality and Consistency

One of the key benefits of using conveyor belt brushes is the improvement in product quality and consistency. By effectively removing debris and contaminants from conveyor belts, these brushes help to prevent product contamination and ensure that products remain clean and intact throughout the manufacturing process. This is particularly important in industries such as food processing, pharmaceuticals, and electronics, where product quality and hygiene standards are paramount.

In addition to maintaining product quality, conveyor belt brushes also contribute to improved consistency in product manufacturing. By ensuring that conveyor belts are clean and free from debris, these brushes help to prevent variations in product quality caused by contamination or irregularities in the production process. This results in more consistent and uniform products, which is essential for meeting customer expectations and regulatory requirements.

Overall, the use of conveyor belt brushes plays a crucial role in enhancing product quality and consistency, ultimately leading to greater customer satisfaction and brand reputation for manufacturing facilities.

Reduction in Maintenance and Downtime

Conveyor belt brushes help to reduce maintenance and downtime by preventing debris and contaminants from accumulating on conveyor belts, which can lead to blockages, jams, or equipment failures. By effectively cleaning the surface of conveyor belts, these brushes help to minimise wear and tear on the equipment, reducing the need for frequent maintenance and repairs. This not only saves time and resources but also extends the lifespan of conveyor belts and associated machinery, leading to long-term cost savings for manufacturing facilities.

Furthermore, the use of conveyor belt brushes can significantly reduce downtime by preventing unexpected stoppages caused by blockages or equipment failures. By maintaining clean conveyor belts, these brushes help to ensure smooth and uninterrupted operation of the production line, minimising disruptions and maximising productivity. This is particularly important for manufacturing facilities with tight production schedules and deadlines, where any downtime can have a significant impact on overall output and profitability.

Overall, the reduction in maintenance and downtime provided by conveyor belt brushes is a valuable benefit for manufacturing facilities looking to improve operational efficiency and reduce costs.

Health and Safety Benefits for Workers

The use of conveyor belt brushes also provides important health and safety benefits for workers in manufacturing facilities. By automating the cleaning process, these brushes help to reduce the need for manual labour in potentially hazardous conditions, such as cleaning conveyor belts in confined spaces or around moving machinery. This helps to minimise the risk of accidents or injuries caused by manual cleaning activities, creating a safer working environment for employees.

In addition to reducing physical risks, conveyor belt brushes also contribute to improved air quality in manufacturing facilities by preventing the accumulation of dust and debris on conveyor belts. This is particularly important for industries such as mining, construction, or metalworking, where airborne particles can pose health risks to workers if not properly controlled. By keeping conveyor belts clean, these brushes help to minimise airborne contaminants, creating a healthier working environment for employees and reducing the risk of respiratory problems or other health issues.

Overall, the health and safety benefits provided by conveyor belt brushes are essential for protecting the well-being of workers in manufacturing facilities. By automating the cleaning process and minimising physical risks and airborne contaminants, these brushes help to create a safer and healthier working environment for employees.

Environmental Benefits of Using Conveyor Belt Brushes

Reducing Waste and Contamination

In addition to improving operational efficiency and worker safety, the use of conveyor belt brushes also provides environmental benefits by reducing waste and improving energy efficiency. By effectively removing debris and contaminants from conveyor belts, these brushes help to prevent product contamination and waste caused by damaged or contaminated products. This not only reduces the amount of waste generated by manufacturing facilities but also minimises the environmental impact of production processes.

Improving Energy Efficiency

Furthermore, the use of conveyor belt brushes helps to improve energy efficiency by maintaining the smooth operation of conveyor belts. Clean conveyor belts require less energy to transport products compared to belts that are clogged with debris or contaminants. This helps to reduce energy consumption and lower carbon emissions associated with manufacturing processes, contributing to environmental sustainability.

Supporting Environmental Conservation

Overall, the environmental benefits provided by conveyor belt brushes are essential for manufacturing facilities looking to reduce their environmental footprint and operate more sustainably. By minimising waste generation and improving energy efficiency, these brushes help to support environmental conservation efforts while also providing long-term cost savings for manufacturing facilities.

Cost Savings and Return on Investment

The use of conveyor belt brushes ultimately leads to cost savings and a positive return on investment for manufacturing facilities. By improving operational efficiency, product quality, worker safety, and environmental sustainability, these brushes help to reduce costs associated with maintenance, downtime, waste generation, energy consumption, and worker health issues. This leads to long-term cost savings for manufacturing facilities while also providing a positive return on investment for the initial investment in conveyor belt brushes.

Furthermore, the extended lifespan of conveyor belts and associated machinery resulting from the use of conveyor belt brushes also contributes to cost savings by reducing the need for frequent repairs or replacements. This helps to lower maintenance costs and capital expenditure on new equipment, providing additional financial benefits for manufacturing facilities. Overall, the cost savings and return on investment provided by conveyor belt brushes make them a valuable investment for manufacturing facilities looking to improve their production processes while also achieving long-term financial benefits.

By enhancing operational efficiency, product quality, worker safety, environmental sustainability, and cost savings, these brushes play a crucial role in supporting the success and profitability of manufacturing facilities.

FAQs

What are conveyor belt brushes?

Conveyor belt brushes are devices used to clean conveyor belts in manufacturing facilities. They are typically made of bristles or other materials and are mounted along the conveyor belt to remove debris, dirt, and other contaminants.

What are the advantages of using conveyor belt brushes in manufacturing?

Using conveyor belt brushes in manufacturing offers several advantages, including improved cleanliness and hygiene, reduced maintenance costs, increased efficiency, and extended conveyor belt life. The brushes help to remove debris and contaminants from the belt, preventing them from accumulating and causing damage or contamination of products being transported.

How do conveyor belt brushes improve cleanliness and hygiene in manufacturing facilities?

Conveyor belt brushes help to remove dirt, debris, and other contaminants from the conveyor belt, preventing them from being transferred to the products being transported. This helps to maintain a clean and hygienic manufacturing environment, reducing the risk of product contamination and ensuring compliance with hygiene standards.

How do conveyor belt brushes reduce maintenance costs?

By removing debris and contaminants from the conveyor belt, conveyor belt brushes help to reduce the wear and tear on the belt and other conveyor components. This can lead to reduced maintenance and repair costs, as well as extended equipment lifespan.

How do conveyor belt brushes increase efficiency in manufacturing?

Conveyor belt brushes help to maintain the smooth operation of conveyor systems by preventing debris and contaminants from causing jams or other disruptions. This can lead to increased productivity and efficiency in manufacturing processes.

How do conveyor belt brushes extend conveyor belt life?

By removing debris and contaminants from the conveyor belt, conveyor belt brushes help to prevent abrasion and damage to the belt surface. This can extend the lifespan of the conveyor belt, reducing the frequency of replacements and associated costs.