Conveyor Belt

Cleaning & Sanitising

Cleaning & Sanitising

Conveyor Belt Cleaning Solutions

DESIGNED FOR ALL TYPES OF CONVEYOR BELTS

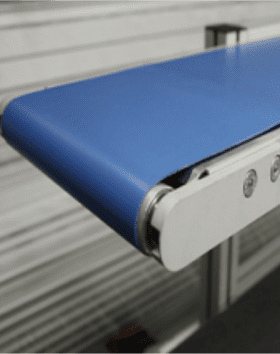

Flat Belt/PVC

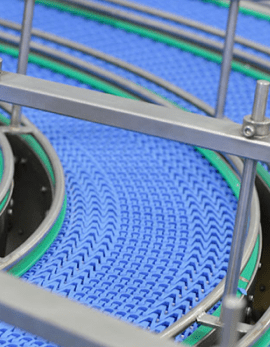

INTERLOCK/MODULAR BELT

FABRIC CONVEYOR BELT

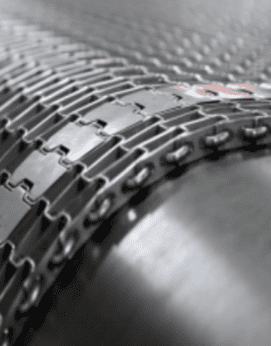

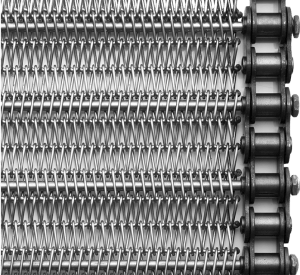

METAL BELT

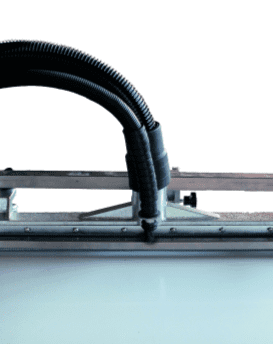

TOP CONVEYOR CLEANING

BOTTOM CONVEYOR CLEANING

PLASTIC BELT

MESH BELT

BENEFITS

operates 24/7

Service is constantly available, 24 hours a day, 7 days a week.

WATER USAGE

Sustainable and cost-effective cleaning disinfects belts and reduces harsh chemical and energy consumption.

DEGREASING OILS

Removes grease, oil, and contaminants.

REMOVE ALLERGENS & CONTAMINATIONS

It helps to create a safer working environment by reducing the risk of allergic reactions, illness, and infection.

CLEANING BETWEEN BREAKS

Cleaning between breaks maintains hygiene, reduces contamination risk, and extends equipment lifespan.

CONTINUOUS CLEANING IN PLACE

Continuous cleaning in place eliminates downtime, improves sanitation, and increases productivity.

THERMAL DISINFECTION

service is constantly available, 24 hours a day, 7 days a week

PORTABLE

It is an ideal solution for facilities with limited space or changing cleaning requirements.

Conveyor Cleaning That Cuts Your Downtime

Conveyor Cleaning That Cuts Your Downtime

Steam, Air, Or UV Powered

Disinfect Conveyor Belts Of Any Type And Size

Disinfect Conveyor Belts of Any Type And Size

Clean During Operation

Customise Your Own

Portable or Fixed System

Continuous Running or During Breaks

Applications of Food Grade Conveyor Belt Cleaners Across Industries

Conveyor belts Steam cleaning solutions ensure thorough and hygienic maintenance across various industries, including pharmaceuticals, fruits and vegetables, bakery production, food processing, confectionery, and cheese and dairy. These cleaning systems meet stringent industrial standards by effectively removing residues, grease, and other contaminants, thereby ensuring food safety and compliance with industry regulations.

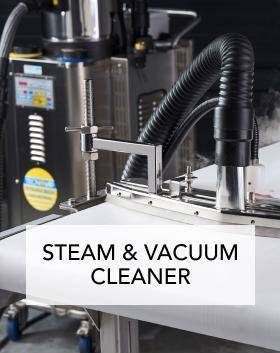

TYPES OF CLEANERS

How Does It Work?

Using a combination of brushes and dry steam vapour generators, our machines are effective at removing particles left over from manufacturing, pharmaceutical debris and food spills.

The end result will leave a clean surface and eliminates any risk of contaminating the next production.It also prevents disease outbreaks, by sanitising surfaces which can harbour food particles which provide nutrients for mould or fungal growth.

How Is It Done?

HIGH TEMPERATURE

Our machines produce dry steam vapour at around 180 degrees Celsius to completely eradicate bacteria. This high temperature blast of dry steam will destroy all living microbes, mould and bacteria.

COMPLETE EXTRACTION

It has an emulsifying effect on any embedded dirt or by-products - allowing them to be extracted by the machine after the brushes have displaced them.

Your staff will work in a cleaner environment, without the risk of disease or outbreaks ruining production or contaminating ingredients.

REDUCE DOWNTIME

An efficient system will get your conveyor line ready to continue working within minutes.

Applying Steam Cleaning

Steam vapour is particularly effective in penetrating the porous surface of conveyor belts and works well in engineering environments such as food handling areas, food preparation work areas or parts factories where parts or components still have oil or grease residue as they travel down the line.

Contaminants are effectively removed from the conveyor, leaving it clean for the next production run.When you need to remove oil, grease, abrasive grime or sludge that builds up constantly. When it is necessary to avoid contamination and prevent the outbreak of a disease with regular production line cleaning.

Dry Cleaning System

The steam vapour produced at more than 180 degrees provides very fast drying with extremely low water content so it will not leave your conveyor soaking wet.

Reduce Water Usage

Let the power of steam vapour do all the work. Sanitise any surface, tool or machine eliminate chemical costs and significantly reduce water usage.

Allergen Cleaning & Sanitising

Some residues can be difficult to remove and carry a risk of contamination and reduce product quality. The heat produced by the steam vapour can remove and kill stubborn allergens.

Tools for Every Cleaning Job

A tool for every job. Our robust and durable accessories perform multiple industrial cleaning applications including machinery, piping, factory and floor cleaning.

blog

Get in touch

Contact Us

Phone: 1800 622 770

Email:

info

conveyorcleaning.com.au