Maintaining hygiene in factories is of utmost importance to ensure the safety of workers and the quality of products. Factories are often busy environments, with various materials and products being transported and processed. Without proper hygiene practices, factories can become breeding grounds for bacteria, contaminants, and other hazards that can compromise the health and safety of workers and the integrity of the products being produced.

Hygiene in factories goes beyond simply keeping the premises clean. It involves implementing effective cleaning and sanitation protocols, ensuring proper waste management, and maintaining a high standard of cleanliness throughout the facility. By prioritising hygiene, factories can create a safe and healthy working environment for their employees, reduce the risk of contamination or product recalls, and uphold their reputation for producing high-quality goods.

The Role of Conveyor Systems in Maintaining Factory Hygiene

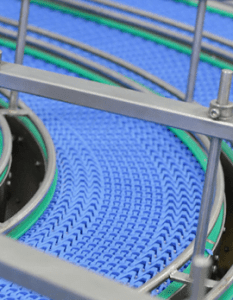

Conveyor systems play a crucial role in maintaining factory hygiene by efficiently transporting materials and products throughout the facility. These systems are commonly used in industries such as manufacturing, food processing, and pharmaceuticals, where large quantities of goods need to be moved from one area to another.

Conveyor systems help to streamline production processes by automating the movement of materials, reducing manual handling and the risk of accidents or injuries. However, if not properly cleaned and maintained, conveyor systems can become a source of contamination and compromise factory hygiene.

Common Challenges Faced in Conveyor Cleaning

Cleaning conveyor systems can present several challenges for factories. One common challenge is time constraints. Factories often operate on tight schedules to meet production targets, leaving little time for thorough cleaning and maintenance. This can result in a build-up of dirt, debris, and contaminants on conveyor belts and other components.

Another challenge is accessing certain areas of the conveyor system for cleaning. Conveyor systems are complex structures with various components that may be difficult to reach or clean effectively. This can lead to areas being overlooked or not cleaned properly, increasing the risk of contamination.

Additionally, some conveyor systems may be used to transport materials that are sticky, greasy, or prone to spillage. This can make cleaning more challenging as these substances can adhere to the conveyor belts and other surfaces, requiring specialised cleaning methods or equipment.

The Benefits of a Top-Notch Conveyor Cleaning System

Investing in a high-quality conveyor cleaning system offers numerous benefits for factories. Firstly, it improves worker safety by reducing the risk of accidents and injuries. Clean conveyor systems are less likely to have slippery surfaces or obstructions that can cause trips or falls. Regular cleaning and maintenance also help identify and address any potential safety hazards before they escalate.

Secondly, a top-notch conveyor cleaning system enhances productivity. Clean conveyor belts and components operate more efficiently, reducing downtime due to breakdowns or malfunctions. By ensuring smooth and uninterrupted material flow, factories can optimise their production processes and meet their targets more effectively.

Furthermore, a clean conveyor system contributes to better product quality. Contaminants or debris on conveyor belts can transfer onto products, compromising their integrity and potentially leading to product recalls or customer complaints. By maintaining a clean conveyor system, factories can ensure that their products meet the required standards and maintain their reputation for quality.

Factors to Consider When Choosing a Conveyor Cleaning System

When choosing a conveyor cleaning system, factories should consider several factors to ensure they select the most suitable option for their specific needs. These factors include:

1. Type of Conveyor System: Different types of conveyor systems require different cleaning methods and equipment. For example, belt conveyors may require different cleaning techniques compared to roller conveyors or screw conveyors. It is important to choose a cleaning system that is compatible with the specific type of conveyor system in use.

2. Cleaning Method: There are various cleaning methods available for conveyor systems, including manual cleaning, automated cleaning, and dry ice blasting. Each method has its advantages and limitations, so factories should consider their specific requirements and constraints when selecting a cleaning method.

3. Cost: The cost of a conveyor cleaning system is an important consideration for factories. It is essential to evaluate the upfront costs of purchasing the equipment, as well as any ongoing maintenance or operational costs. Factories should also consider the potential return on investment in terms of improved productivity, product quality, and worker safety.

Understanding Different Types of Conveyor Cleaning Systems

There are different types of conveyor cleaning systems available, each with its advantages and applications. Understanding these different types can help factories make an informed decision when choosing a conveyor cleaning system.

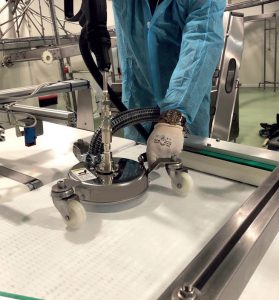

1. Manual Cleaning: Manual cleaning involves physically removing dirt, debris, and contaminants from the conveyor system using tools such as brushes, scrapers, or high-pressure water jets. This method is suitable for smaller conveyor systems or areas that are difficult to access with automated equipment. However, it can be time-consuming and labour-intensive.

2. Automated Cleaning: Automated cleaning systems use specialized equipment to clean conveyor belts and components automatically. These systems may include brushes, sprayers, or vacuum systems that remove dirt and debris from the conveyor system. Automated cleaning is more efficient and less labour-intensive than manual cleaning, making it suitable for larger conveyor systems or factories with high production volumes.

3. Dry Ice Blasting: Dry ice blasting is a non-abrasive cleaning method that uses compressed air to propel dry ice pellets onto the conveyor system’s surfaces. The dry ice pellets sublimate upon impact, lifting away dirt and contaminants without leaving any residue behind. Dry ice blasting is effective for removing stubborn substances such as grease or adhesives and is environmentally friendly as it does not use chemicals or water.

How to Effectively Implement a Conveyor Cleaning System in Your Factory

Implementing a conveyor cleaning system in a factory requires careful planning and execution. Here are some tips and best practices to ensure effective implementation:

1. Create a Cleaning Schedule: Establish a regular cleaning schedule that outlines when and how the conveyor system will be cleaned. This schedule should take into account production schedules, downtime, and any specific cleaning requirements for different areas or components of the conveyor system.

2. Provide Training to Workers: Provide comprehensive training to workers on proper cleaning techniques, safety protocols, and the use of cleaning equipment. This will ensure that cleaning tasks are carried out effectively and safely.

3. Use Appropriate Cleaning Agents: Select cleaning agents that are suitable for the specific type of conveyor system and the materials being transported. Avoid using harsh chemicals that may damage the conveyor belts or components.

4. Regular Inspections: Conduct regular inspections of the conveyor system to identify any maintenance or cleaning needs. Address any issues promptly to prevent them from escalating or causing disruptions to production.

Maintenance and Upkeep of Conveyor Cleaning Systems

Regular maintenance and upkeep of conveyor cleaning systems are essential to ensure their effectiveness and longevity. Here are some key maintenance practices:

1. Regular Cleaning: Clean the conveyor cleaning system regularly to remove any dirt, debris, or contaminants that may have accumulated. This will help maintain its efficiency and prevent any build-up that could compromise its performance.

2. Lubrication: Apply lubricants to moving parts of the conveyor system to reduce friction and wear. This will help extend the lifespan of the equipment and ensure smooth operation.

3. Inspection and Repairs: Regularly inspect the conveyor cleaning system for any signs of wear, damage, or malfunction. Address any issues promptly by repairing or replacing damaged components to prevent further damage or breakdowns.

4. Training and Education: Continuously train workers on proper maintenance procedures and best practices for using the conveyor cleaning system. This will help ensure that the equipment is used correctly and that any potential issues are identified early on.

Case Studies: Real-Life Examples of Improved Factory Hygiene with Conveyor Cleaning Systems

There are numerous examples of factories that have successfully implemented conveyor cleaning systems and seen significant improvements in hygiene, safety, and productivity. One such example is a food processing plant that invested in an automated conveyor cleaning system. Before implementing the system, the plant faced challenges with contamination and product recalls due to inadequate cleaning practices. After installing the automated cleaning system, the plant saw a significant reduction in contamination incidents and an improvement in product quality. The system allowed for more efficient and thorough cleaning, ensuring that the conveyor belts were free from any contaminants that could compromise food safety.

Another example is a manufacturing facility that used dry ice blasting as a cleaning method for their conveyor system. The facility had previously struggled with removing stubborn substances such as grease and adhesives from the conveyor belts. By implementing dry ice blasting, they were able to effectively remove these substances without causing any damage to the belts or components. This improved the overall cleanliness of the conveyor system and reduced the risk of contamination or product defects.

Investing in a Conveyor Cleaning System for a Cleaner, Safer Factory

Maintaining hygiene in factories is crucial for the safety of workers and the quality of products. Conveyor systems play a vital role in maintaining factory hygiene by efficiently transporting materials and products throughout the facility. However, cleaning and maintaining these systems can present challenges such as time constraints and difficulty accessing certain areas.

Investing in a top-notch conveyor cleaning system offers numerous benefits, including improved worker safety, increased productivity, and better product quality. When choosing a conveyor cleaning system, factories should consider factors such as the type of conveyor system, the cleaning method, and the cost.

Implementing a conveyor cleaning system requires careful planning and execution, including creating a cleaning schedule, training workers, using appropriate cleaning agents, and conducting regular inspections. Regular maintenance and upkeep of conveyor cleaning systems are essential to ensure their effectiveness and longevity.

Real-life examples have shown the positive impact of conveyor cleaning systems on factory hygiene, safety, and productivity. By investing in a conveyor cleaning system, factories can create a cleaner and safer working environment, reduce the risk of contamination or product recalls, and uphold their reputation for producing high-quality goods.

If you’re in the food manufacturing industry, you know how crucial it is to maintain a clean and hygienic environment. One essential aspect of food safety is conveyor belt cleaning. A recent article on Conveyor Cleaning’s website explores the three reasons why conveyor belt cleaning is essential for food safety. It highlights the importance of preventing cross-contamination, reducing the risk of product recalls, and ensuring compliance with food safety regulations. To learn more about this topic, check out the article here.

FAQs

What is a conveyor cleaning system?

A conveyor cleaning system is a set of equipment and processes designed to clean conveyor belts and other conveyor components to maintain hygiene and prevent contamination in food processing, pharmaceutical, and other industries.

What are the benefits of using a conveyor cleaning system?

Using a conveyor cleaning system can help prevent contamination, reduce downtime, increase productivity, and improve safety in the workplace. It can also extend the lifespan of conveyor components and reduce maintenance costs.

What are the components of a conveyor cleaning system?

A conveyor cleaning system typically includes a conveyor belt cleaner, a conveyor belt scraper, a conveyor belt brush, a conveyor belt washing system, and a conveyor belt drying system. Other components may include a conveyor belt tracking system, a conveyor belt tensioning system, and a conveyor belt inspection system.

How does a conveyor cleaning system work?

A conveyor cleaning system works by removing debris, dirt, and other contaminants from the conveyor belt and other conveyor components. This is typically done using a combination of mechanical and chemical cleaning methods, such as scraping, brushing, washing, and drying.

What types of conveyor cleaning systems are available?

There are several types of conveyor cleaning systems available, including manual cleaning systems, semi-automatic cleaning systems, and fully automatic cleaning systems. The type of system used will depend on the specific needs and requirements of the industry and application.

What factors should be considered when selecting a conveyor cleaning system?

When selecting a conveyor cleaning system, factors such as the type of conveyor, the type of product being conveyed, the level of contamination, and the required level of hygiene should be considered. Other factors may include the size and layout of the facility, the available space and resources, and the budget for the system.