Conveyor belt cleaning is a crucial aspect of maintaining efficient and safe material handling operations in industries such as mining, agriculture, food processing and manufacturing. Traditional conveyor belt cleaning methods often involve manual labour, which can be time-consuming, costly and potentially hazardous. However, the revolutionary conveyor belt cleaning system offers a significant improvement to these challenges.

This innovative system utilises advanced technology to automate and streamline the cleaning process, resulting in improved efficiency, reduced downtime and enhanced workplace safety. This article will explore the need for innovation in conveyor belt cleaning, how the revolutionary system functions, its advantages, case studies of its implementation, a comparison with traditional methods, and future developments and potential applications.

Summary

- The Revolutionary Conveyor Belt Cleaning System is a game-changer in the industry, offering a new and innovative approach to keeping conveyor belts clean and efficient.

- Innovation in conveyor belt cleaning is crucial for improving productivity, reducing maintenance costs, and ensuring a safe working environment.

- The Revolutionary Conveyor Belt Cleaning System uses advanced technology to effectively remove debris and spillage, improving belt performance and reducing downtime.

- The system offers benefits such as increased conveyor belt lifespan, reduced manual labour, and improved safety and hygiene standards.

- Case studies demonstrate the successful implementation of the Revolutionary Conveyor Belt Cleaning System, showcasing its impact on various industries and applications.

The Need for Innovation in Conveyor Belt Cleaning

Safety Concerns and Inefficiencies

Manual cleaning processes often require workers to physically access the conveyor belt, exposing them to potential safety hazards such as moving parts, pinch points, and hazardous materials. Moreover, manual cleaning can be time-consuming and labour-intensive, leading to increased downtime and operational costs.

Ineffective Debris Removal

In addition, traditional cleaning methods may not effectively remove stubborn debris, resulting in reduced conveyor belt performance and increased risk of material spillage. These challenges highlight the need for a revolutionary conveyor belt cleaning system that can automate and improve the cleaning process while prioritising worker safety and operational efficiency.

A Revolutionary Solution

The revolutionary conveyor belt cleaning system addresses these needs by leveraging advanced technology to automate and optimise the cleaning process. By doing so, it reduces the reliance on manual labour, minimises downtime, and enhances workplace safety. Furthermore, the system’s innovative design and functionality enable it to effectively remove debris and maintain optimal conveyor belt performance. As a result, industries can benefit from improved productivity, reduced maintenance costs, and a safer work environment.

How the Revolutionary Conveyor Belt Cleaning System Works

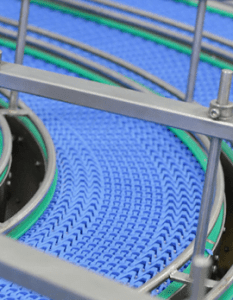

The revolutionary conveyor belt cleaning system operates through a combination of advanced technologies and innovative design features. At its core, the system utilises automated cleaning mechanisms that are integrated into the conveyor belt structure. These mechanisms can include high-pressure water jets, brushes, scrapers, or air knives, depending on the specific requirements of the application.

The system is designed to be fully adjustable and customisable to accommodate different conveyor belt sizes, materials, and operating conditions. In operation, the cleaning system is activated at pre-determined intervals or in response to real-time monitoring of conveyor belt conditions. This automation minimises the need for manual intervention and ensures consistent and thorough cleaning performance.

The system’s advanced sensors and monitoring capabilities enable it to detect debris build-up, material spillage, or other issues that may impact conveyor belt performance. As a result, the system can proactively address these issues before they escalate into more significant problems. Furthermore, the revolutionary conveyor belt cleaning system can be integrated with existing conveyor belt infrastructure or incorporated into new conveyor belt installations.

Its modular design and flexible configuration options make it adaptable to a wide range of industry applications. Overall, the system’s innovative approach to automated cleaning sets it apart from traditional methods and positions it as a game-changing solution for improving conveyor belt maintenance and performance.

Benefits of the Revolutionary Conveyor Belt Cleaning System

| Benefits | Revolutionary Conveyor Belt Cleaning System |

|---|---|

| Increased Efficiency | Reduces downtime and maintenance, leading to higher productivity |

| Cost Savings | Decreases the need for frequent belt replacements and manual cleaning labour |

| Improved Safety | Minimises the risk of accidents and injuries associated with manual cleaning methods |

| Environmental Impact | Reduces water and chemical usage, promoting sustainability |

| Extended Belt Life | Prevents premature wear and tear, extending the lifespan of conveyor belts |

The revolutionary conveyor belt cleaning system offers a multitude of benefits that address the key challenges associated with traditional cleaning methods. Firstly, the system significantly reduces the need for manual labour, thereby minimising worker exposure to safety hazards and reducing labour costs. This improvement in workplace safety is a crucial advantage that contributes to a healthier and more productive work environment.

Secondly, the automated nature of the cleaning system results in enhanced operational efficiency and reduced downtime. By proactively addressing debris build-up and material spillage, the system helps maintain optimal conveyor belt performance and minimises the risk of unplanned maintenance or production stoppages. This increased reliability and uptime translate into improved productivity and cost savings for industries that rely on conveyor belt operations.

Additionally, the revolutionary conveyor belt cleaning system’s ability to effectively remove debris and maintain clean conveyor belts contributes to a reduction in material wastage and environmental impact. By preventing material spillage and contamination, the system supports sustainable practices and regulatory compliance within various industries. Furthermore, the system’s modular design and customisable features make it adaptable to diverse conveyor belt configurations and operating conditions.

This flexibility ensures that industries can tailor the system to their specific needs and achieve optimal cleaning performance. Overall, the revolutionary conveyor belt cleaning system offers a comprehensive set of benefits that address the limitations of traditional cleaning methods while delivering tangible improvements in safety, efficiency, sustainability, and cost-effectiveness.

Case Studies: Success Stories of Implementing the Revolutionary Conveyor Belt Cleaning System

Several industries have successfully implemented the revolutionary conveyor belt cleaning system with remarkable results. In the mining sector, for example, a large-scale operation integrated the system into its material handling infrastructure to address persistent challenges related to material spillage and conveyor belt maintenance. By automating the cleaning process and proactively managing debris build-up, the system significantly reduced downtime and maintenance costs while improving workplace safety.

In the food processing industry, a leading manufacturer implemented the revolutionary cleaning system to enhance hygiene standards and compliance with food safety regulations. The system’s advanced cleaning mechanisms effectively removed food residues and contaminants from conveyor belts, ensuring product integrity and consumer safety. As a result, the manufacturer achieved improved quality control and regulatory compliance while streamlining its cleaning processes.

Furthermore, in agricultural applications such as grain handling facilities, the revolutionary conveyor belt cleaning system has proven instrumental in preventing material spillage and contamination during bulk material handling operations. By maintaining clean conveyor belts and minimising material wastage, these facilities have achieved greater operational efficiency and reduced environmental impact. These case studies demonstrate the diverse applications and tangible benefits of implementing the revolutionary conveyor belt cleaning system across different industries.

The system’s ability to address specific operational challenges while delivering improvements in safety, efficiency, and compliance underscores its value as a transformative solution for conveyor belt maintenance.

Comparison with Traditional Conveyor Belt Cleaning Methods

Reduced Labour and Improved Safety

Traditional methods often rely on manual labour for cleaning operations, which can be time-consuming, labour-intensive, and potentially hazardous. In contrast, the revolutionary system automates the cleaning process through advanced technologies such as high-pressure water jets, brushes, scrapers, or air knives. This automation reduces the reliance on manual labour while ensuring consistent and thorough cleaning performance.

Effective Debris Removal and Prevention of Material Spillage

Traditional methods may struggle to effectively remove stubborn debris or prevent material spillage due to their limitations in reach or cleaning intensity. The revolutionary conveyor belt cleaning system overcomes these challenges by leveraging advanced sensors and monitoring capabilities to detect debris build-up and proactively address it with targeted cleaning mechanisms. This proactive approach minimises the risk of material spillage and ensures optimal conveyor belt performance.

Flexibility and Adaptability

Traditional methods may lack flexibility in adapting to different conveyor belt configurations or operating conditions. The revolutionary system’s modular design and customisable features make it adaptable to diverse industry applications, allowing for tailored solutions that optimise cleaning performance.

Overall, when compared to traditional methods, the revolutionary conveyor belt cleaning system offers significant advantages in terms of safety, efficiency, reliability, and adaptability. Its innovative approach to automated cleaning sets a new standard for conveyor belt maintenance and performance.

Future Developments and Potential Applications of the Revolutionary Conveyor Belt Cleaning System

Looking ahead, future developments in the revolutionary conveyor belt cleaning system are poised to expand its potential applications and capabilities even further. Advancements in sensor technology, data analytics, and artificial intelligence are expected to enhance the system’s monitoring capabilities and predictive maintenance features. This will enable industries to proactively manage conveyor belt maintenance and performance with greater precision and efficiency.

Furthermore, ongoing research and development efforts are focused on integrating sustainable practices into the system’s design. This includes exploring alternative cleaning agents, energy-efficient technologies, and recyclable materials to minimise environmental impact while maintaining optimal cleaning performance. In terms of potential applications, the revolutionary conveyor belt cleaning system is well-positioned to address a wide range of material handling challenges across industries such as mining, agriculture, food processing, manufacturing, logistics, and more.

Its adaptability to diverse conveyor belt configurations and operating conditions makes it suitable for various material types, sizes, and environmental conditions. Overall, future developments in the revolutionary conveyor belt cleaning system hold promise for further enhancing its value proposition as a transformative solution for improving safety, efficiency, sustainability, and cost-effectiveness in material handling operations. In conclusion, the revolutionary conveyor belt cleaning system represents a significant advancement in addressing the challenges associated with traditional cleaning methods.

Its innovative approach to automated cleaning offers tangible benefits in terms of safety, efficiency, reliability, adaptability while reducing environmental impact. Success stories from various industries demonstrate its diverse applications and transformative impact on conveyor belt maintenance. When compared with traditional methods, it stands out as a game-changing solution that sets new standards for material handling operations.

Looking ahead, future developments are expected to expand its potential applications further while enhancing its capabilities through advanced technologies and sustainable practices. Overall, the revolutionary conveyor belt cleaning system is poised to play a pivotal role in shaping the future of material handling operations across industries worldwide.

If you are interested in learning more about the importance of conveyor belt cleaning for food safety, you should check out this article on 3 Reasons Why Conveyor Belt Cleaning is Essential for Food Safety. This article discusses the critical role that a clean conveyor belt plays in preventing food contamination and ensuring the safety of the products being transported. It provides valuable insights into the potential risks of neglecting conveyor belt cleaning and highlights the necessity of implementing an effective cleaning system.

FAQs

What is a conveyor belt cleaning system?

A conveyor belt cleaning system is a set of equipment and devices designed to remove debris, spillage, and other contaminants from conveyor belts to ensure efficient and safe operation.

Why is conveyor belt cleaning important?

Conveyor belt cleaning is important to maintain the efficiency of the conveyor system, prevent material build-up, reduce the risk of equipment damage, and ensure a safe working environment.

What are the components of a conveyor belt cleaning system?

A conveyor belt cleaning system typically includes primary and secondary belt cleaners, belt scrapers, belt brushes, and other accessories such as belt skirting and belt ploughs.

How does a conveyor belt cleaning system work?

The primary belt cleaner is positioned on the head pulley to remove the bulk of the carryback material, while the secondary belt cleaner is installed further down the belt to provide additional cleaning. Belt scrapers and brushes are used to remove stubborn residue and fine particles.

What are the benefits of using a conveyor belt cleaning system?

Using a conveyor belt cleaning system can improve conveyor performance, reduce maintenance costs, extend belt life, and enhance workplace safety by minimizing the risk of accidents and injuries.

How do I choose the right conveyor belt cleaning system for my application?

When selecting a conveyor belt cleaning system, factors to consider include the type of material being conveyed, belt speed, belt width, and the specific cleaning requirements of the application. It is advisable to consult with a professional to determine the most suitable system for your needs.