Steam conveyor belt cleaning is a method used to effectively and efficiently clean conveyor belts in production lines. Conveyor belts are an integral part of many industries, including manufacturing, food processing, and packaging. They are used to transport materials and products from one area to another. Over time, conveyor belts can become dirty and contaminated with various substances, such as dirt, grease, and food particles. This can lead to a range of issues, including reduced efficiency, increased risk of contamination, and product recalls. Steam cleaning offers a solution to these problems by providing a thorough and hygienic cleaning method.

Keeping conveyor belts clean is crucial in production lines for several reasons. Firstly, dirty conveyor belts can affect the efficiency of the production process. When belts are clogged with dirt and debris, they may not run smoothly or at their optimal speed. This can result in delays and disruptions in the production line, leading to decreased productivity and increased costs. Additionally, dirty conveyor belts can pose a risk of contamination. In industries such as food processing, maintaining high hygiene standards is essential to prevent the spread of bacteria and other pathogens. Contaminated products can lead to serious health risks for consumers and may result in costly product recalls.

The Importance of Clean Conveyor Belts in Production Lines

The risks associated with dirty conveyor belts in production lines are significant. Contamination can occur when dirt, grease, or other substances on the belt come into contact with the products being transported. This can happen through direct contact or through airborne particles that settle on the products. Contaminated products can cause illness or injury to consumers and can damage a company’s reputation. In some cases, product recalls may be necessary, resulting in financial losses and damage to brand image.

Maintaining hygiene standards is crucial in industries such as food processing where strict regulations are in place to ensure consumer safety. Conveyor belts that are not properly cleaned can harbor bacteria and other pathogens, which can contaminate food products. This can lead to foodborne illnesses and outbreaks, which can have severe consequences for both consumers and businesses. By implementing steam conveyor belt cleaning, companies can ensure that their production lines meet the necessary hygiene standards and reduce the risk of contamination.

Benefits of Steam Cleaning over Traditional Cleaning Methods

Steam cleaning offers several advantages over traditional cleaning methods when it comes to conveyor belt cleaning. Firstly, steam cleaning is highly efficient and effective in removing dirt, grease, and other substances from conveyor belts. The high temperature of the steam helps to break down and dissolve stubborn stains and grime, making it easier to remove. Steam also has the ability to penetrate into hard-to-reach areas, ensuring a thorough clean.

Compared to other methods such as manual scrubbing or pressure washing, steam cleaning is less labor-intensive. It requires less physical effort and can be done more quickly, allowing for increased productivity in the production line. Additionally, steam cleaning does not require the use of harsh chemicals or detergents, making it a safer and more environmentally friendly option. This is particularly important in industries where strict regulations govern the use of chemicals and their impact on the environment.

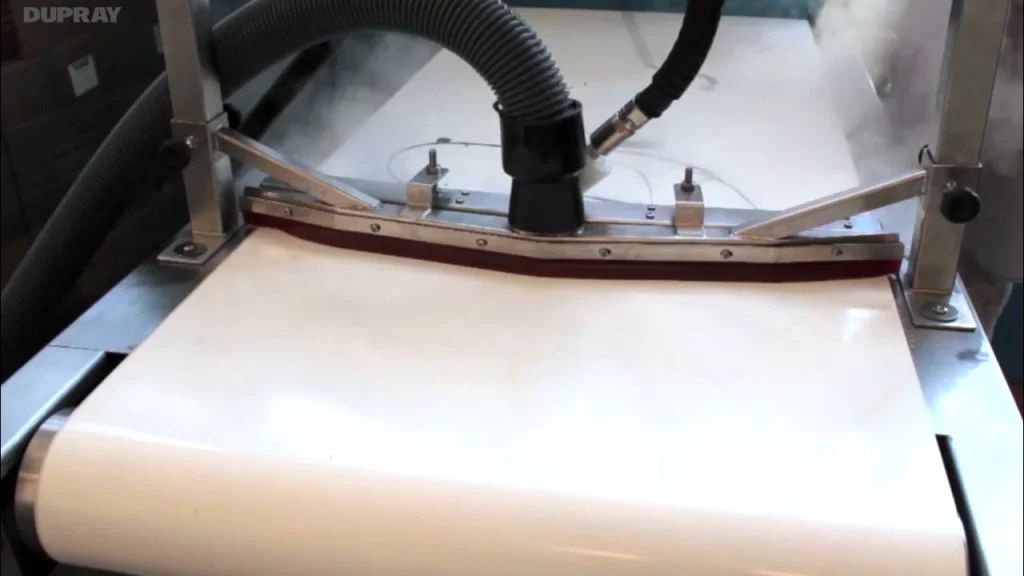

How Steam Conveyor Belt Cleaning Works

Steam conveyor belt cleaning involves the use of high-temperature steam to remove dirt and grime from conveyor belts. The process typically involves the following steps:

1. Preparing the equipment: Before starting the steam cleaning process, it is important to ensure that all necessary equipment is in place and functioning properly. This includes the steam cleaner, hoses, and attachments.

2. Pre-cleaning: Before applying steam, any loose debris or large particles should be removed from the conveyor belt using a vacuum or brush. This helps to ensure that the steam can effectively penetrate and clean the surface.

3. Applying steam: Once the pre-cleaning is complete, steam is applied to the conveyor belt using a steam cleaner. The steam is directed onto the surface of the belt, targeting areas that are particularly dirty or stained.

4. Agitating and wiping: After the steam has been applied, a brush or cloth can be used to agitate the surface of the belt and help loosen any remaining dirt or grime. The steam cleaner can also be used to wipe away the loosened debris.

5. Drying: Once the cleaning process is complete, the conveyor belt should be allowed to dry thoroughly before being put back into use. This can be done using fans or by simply allowing the belt to air dry.

Equipment Required for Steam Conveyor Belt Cleaning

To effectively steam clean conveyor belts, several pieces of equipment are required. These include:

1. Steam cleaner: A high-quality steam cleaner is essential for steam conveyor belt cleaning. It should have a high-pressure steam output and adjustable temperature settings to ensure optimal cleaning results. The cleaner should also have attachments and accessories specifically designed for cleaning conveyor belts.

2. Hoses and attachments: Hoses and attachments are used to direct the steam onto the conveyor belt surface. They should be flexible and easy to maneuver, allowing for thorough cleaning of all areas of the belt.

3. Brushes and cloths: Brushes and cloths are used to agitate the surface of the conveyor belt and help remove dirt and grime. They should be made of durable materials that can withstand high temperatures and repeated use.

4. Fans or drying equipment: After steam cleaning, it is important to allow the conveyor belt to dry thoroughly before putting it back into use. Fans or other drying equipment can be used to speed up the drying process.

Safety Precautions for Steam Cleaning Conveyor Belts

When using steam cleaning equipment, it is important to take certain safety precautions to prevent accidents and injuries. Firstly, operators should wear appropriate personal protective equipment (PPE), such as gloves and safety goggles, to protect themselves from steam and any debris that may be dislodged during the cleaning process. It is also important to ensure that the steam cleaner is used in a well-ventilated area to prevent the buildup of steam and fumes.

Operators should be trained on how to properly use the steam cleaning equipment and should follow all manufacturer instructions and guidelines. This includes ensuring that the equipment is properly maintained and inspected regularly for any signs of damage or malfunction. Additionally, operators should be aware of any potential hazards in the area where the cleaning is taking place, such as trip hazards or electrical outlets, and take appropriate precautions to prevent accidents.

Cost Savings and Increased Efficiency with Steam Cleaning

Implementing steam conveyor belt cleaning can result in significant cost savings and increased efficiency for companies. Firstly, steam cleaning is a more efficient method compared to traditional cleaning methods such as manual scrubbing or pressure washing. It requires less time and effort, allowing for increased productivity in the production line. This can result in cost savings by reducing labor costs and minimizing downtime.

Additionally, steam cleaning does not require the use of harsh chemicals or detergents, which can be expensive to purchase and dispose of. This can result in cost savings for companies, particularly in industries where large quantities of cleaning chemicals are typically used. Steam cleaning also eliminates the need for water-intensive cleaning methods, reducing water consumption and associated costs.

Environmental Benefits of Steam Conveyor Belt Cleaning

Steam conveyor belt cleaning offers several environmental benefits compared to traditional cleaning methods. Firstly, steam cleaning does not require the use of harsh chemicals or detergents, which can be harmful to the environment. This reduces the release of pollutants into the air and water systems, helping to protect ecosystems and wildlife.

Additionally, steam cleaning uses significantly less water compared to traditional cleaning methods such as pressure washing. This helps to conserve water resources, particularly in areas where water scarcity is a concern. Steam cleaning also eliminates the need for wastewater treatment and disposal, reducing the environmental impact associated with traditional cleaning methods.

Case Studies: Successful Implementation of Steam Conveyor Belt Cleaning

Several companies have successfully implemented steam conveyor belt cleaning and have seen significant benefits as a result. For example, a food processing company in the UK implemented steam cleaning in their production line to ensure high hygiene standards. They found that steam cleaning was more effective in removing dirt and grime compared to their previous cleaning method of manual scrubbing. This resulted in improved cleanliness and reduced risk of contamination.

Another case study involves a manufacturing company that implemented steam conveyor belt cleaning to increase efficiency in their production line. They found that steam cleaning reduced the time required for cleaning and allowed for faster turnaround times between production runs. This resulted in increased productivity and cost savings for the company.

Why Your Production Line Needs Steam Conveyor Belt Cleaning

In conclusion, steam conveyor belt cleaning is an effective and efficient method for keeping conveyor belts clean in production lines. Dirty conveyor belts can negatively impact production efficiency and pose a risk of contamination, leading to product recalls and damage to brand reputation. Steam cleaning offers several advantages over traditional cleaning methods, including increased efficiency, effectiveness, and environmental friendliness.

By implementing steam conveyor belt cleaning, companies can save costs, increase efficiency, and maintain high hygiene standards. The process involves using high-temperature steam to remove dirt and grime from conveyor belts, and requires specific equipment such as a steam cleaner, hoses, attachments, brushes, and cloths. Safety precautions should be taken when using steam cleaning equipment to prevent accidents and injuries.

Several case studies have shown the successful implementation of steam conveyor belt cleaning in various industries, resulting in improved cleanliness, increased productivity, and cost savings. Therefore, it is important for companies to consider implementing steam cleaning in their production lines to ensure optimal performance and maintain high hygiene standards.

If you’re looking to maximize efficiency with a modular conveyor belt cleaning system, then you’ll definitely want to check out this informative article from Conveyor Cleaning Australia. This article provides valuable insights into the benefits of using a modular system for conveyor belt cleaning, including improved cleaning efficiency and reduced downtime. With a focus on automated dry steam cleaning, this article highlights the importance of choosing the right equipment for optimal performance. To learn more about how a modular conveyor belt cleaning system can enhance your operations, click here.

FAQs

What is steam conveyor belt cleaning?

Steam conveyor belt cleaning is a method of cleaning conveyor belts using high-pressure steam. It is an effective and environmentally friendly way of removing dirt, grime, and other contaminants from conveyor belts.

How does steam conveyor belt cleaning work?

Steam conveyor belt cleaning works by using high-pressure steam to break down and remove dirt, grime, and other contaminants from conveyor belts. The steam is applied to the conveyor belt using a specially designed steam cleaning machine.

What are the benefits of steam conveyor belt cleaning?

The benefits of steam conveyor belt cleaning include improved hygiene, reduced downtime, increased productivity, and reduced water usage. Steam cleaning is also environmentally friendly, as it does not require the use of harsh chemicals.

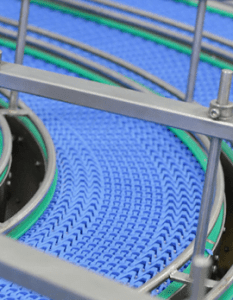

What types of conveyor belts can be cleaned using steam?

Steam conveyor belt cleaning can be used on a wide range of conveyor belts, including fabric, plastic, and metal belts. It is suitable for use in a variety of industries, including food and beverage, pharmaceuticals, and manufacturing.

Is steam conveyor belt cleaning safe?

Yes, steam conveyor belt cleaning is safe when carried out by trained professionals using the correct equipment. The high-pressure steam used in the cleaning process can be dangerous if not handled properly, so it is important to use a reputable cleaning company with experienced technicians.

How often should conveyor belts be steam cleaned?

The frequency of steam conveyor belt cleaning will depend on a variety of factors, including the type of conveyor belt, the industry, and the level of contamination. In general, it is recommended that conveyor belts be steam cleaned at least once a year, but more frequent cleaning may be necessary in some cases.