Pharmaceutical Conveyor Belt Sanitising

Improved hygiene

Compliance with regulations

Increased productivity

Cost savings

Reputation management

Sanitising Conveyors in Pharmaceutical Plants

Using high temperature pressurised steam to clean pharmaceutical transport belts makes perfect sense- and provides a superior clean. There are no chemicals introduced during the cleaning process- so there's absolutely no risk of cross-contamination with medications.

Steam vapour exits the nozzles at 160 Degrees Centigrade, breaking down contaminants instantly. The high exit temperature means the steam is effectively sterilising the belt surface- with the advantage of rendering the conveyor ready for work, within minutes.

Broken tablet fragments, powdered residue and emulsified gels from capsules are all effectively removed, using our conveyor cleaning system.

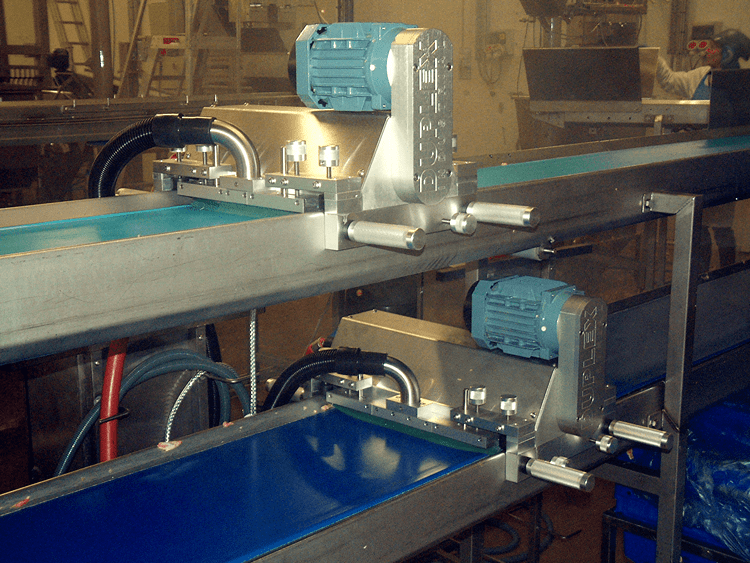

Custom Configurations

The boiler and nozzles can be configured optimally within any work environment. steam discharge heads can be custom-designed within our units, to evenly cover all standard conveyor widths, from 80cm to 210cm.

Placement of our boilers and output devices can be optimised for any production line and work environment. Specialised designs and custom builds are available- our engineers can work with you to create a system that saves you time, money and labour.

There is no risk to the product- no compromise of line purity and no hazard to personnel. Unlike manual cleaning with isopropyl alcohol- a correctly set up and calibrated high-power steam vapour system will ensure complete surface decontamination. Our system doesn't rely on people manually wiping down conveyors- so the risk of incomplete surface treatment is gone.

Complete Removal of Contaminants

The steam output is at high pressure- which means it's strong enough to blast away and completely eliminate broken pill fragments and contaminants which might stick to the conveyor line within a pharmaceutical manufacturing facility.

The high temperature output destroys bacteria, and makes for safer work conditions for operators. Particles or residues from damaged products are blasted away and the belt is cleaned and sanitised all in one pass.

This is the best way to eliminate the risk of cross-contamination of pharmaceutical transport systems and conveyors in manufacturing before products reach the packaging area.

Pharmaceutical Production

Clean conveyor belts are used in transporting pharmaceutical products during manufacture and packaging.

Prevent disease outbreaks.

Sanitise conveyors

Vacuum dust

Deep clean difficult access areas.

Steam-Clean Food Conveyors

Sanitise food processing factory conveyor belts, to prevent cross-contamination of ingredients.

Reduce the risk of spoiling products.

Remove food build-up

Thoroughly clean conveyors

Clean food benches, & storage areas.

Engineering Conveyor Cleanliness

Maintain clean parts handling conveyors- keep foreign debris at bay. Eliminate all unwanted substances.

Package and supply clean parts.

Clean faster, use fewer resources;

Melt grime using steam.