Interlock/Modular Conveyor Belt Cleaning

Factories often face the challenge of cleaning conveyor belts, which requires dismantling and transferring the belts to a wet room for cleaning. The process involves waiting for the belts to dry before reinstalling and sanitising them, leading to extended downtime and reduced production, resulting in financial losses.

Conveyor Cleaning provides a more efficient and cost-effective solution with their Interlock/Modular Conveyor Belt Cleaning system, which is suitable for situations where wet cleaning is not feasible.

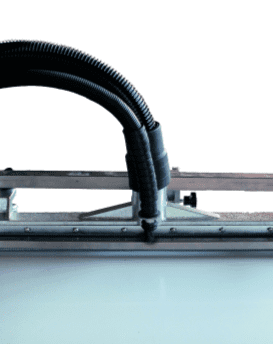

This system uses dry steam cleaning, eliminating the need for dismantling machinery or removing belts. It is placed over the conveyor belts and operates while the belt passes through, cleaning the system thoroughly.

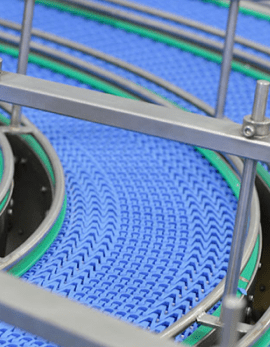

Interlock/Modular Conveyor Belts are commonly utilised in various applications, particularly in dry bakery environments such as bread factories.

While they are crucial for cooling food products, these conveyors have a complicated belt structure that makes cleaning challenging.

This complexity may result in trapped debris accumulation, which can harbour mould that could spread to the produce.

Our Interlock/Modular Belts are available in both brush-type and brushless styles and offer one of the most productive cleaning methods for all types of food factories.

Both systems use steam to break down debris and efficiently remove it using our efficient vacuum collector, leaving the belt clean, dry and sanitised.

Our steam generator provides perfectly delivered steam with a pressure of up to 10 Bar, eliminating the need for harsh chemicals.

Our steam conveyor belt hygiene solutions are not only effective but also environmentally friendly and cost-effective.

DESIGNED FOR ALL TYPES OF CONVEYOR BELTS

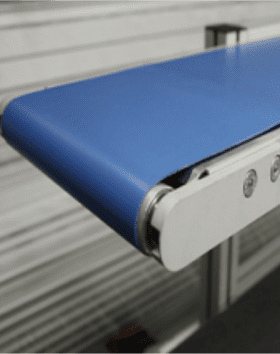

FLAT BELT/PVC

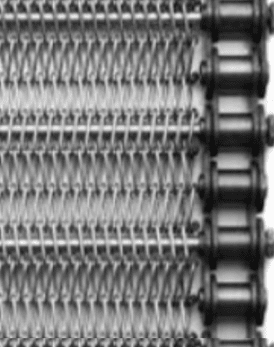

INTERLOCK/MODULAR BELT

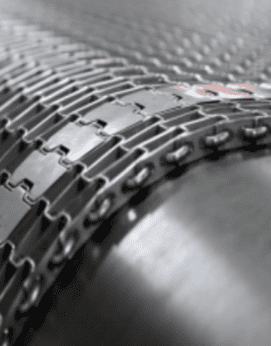

FABRIC CONVEYOR BELT

METAL BELT

TOP CONVEYOR CLEANING

BOTTOM CONVEYOR CLEANING

PLASTIC BELT