In the ever-evolving landscape of industrial and manufacturing operations, efficiency is the name of the game. The pursuit of streamlined processes, improved safety measures, and sustainability initiatives drive companies to explore innovative solutions. A solution that has been making waves in the industry is the interlock conveyor belt system. In this article, we will delve into the world of interlock belts, shedding light on what they are, their different types, and how they are revolutionising various aspects of manufacturing and logistics. So, fasten your seatbelts – or should we say, conveyor belts – as we embark on this journey of discovery.

What is an Interlock Conveyor Belt?

Before we dive into the intricacies of interlock belts, let’s define what they are. An interlock conveyor belt is a system that utilises interconnected modules or links to form a continuous surface. This modular belt approach allows for flexibility, durability, and ease of maintenance, making them a preferred choice in industries where conveyor systems play a crucial role.

Different Types of Interlock Conveyors

Interlock systems can be broadly classified into two categories: safety interlocks and non-safe interlocks.

1) Safety Interlocks

Safety should always be a top priority in industrial settings. Safety interlocks are mechanisms designed to ensure the protection of workers and equipment. These interlocks prevent the conveyor system from operating when certain safety conditions are not met. For example, a safety interlock might prevent the conveyor from starting unless all access doors are securely closed, reducing the risk of accidents and injuries.

2) Non-Safe Interlocks

Non-safe interlocks, on the other hand, are mechanisms that do not directly relate to safety but can enhance the efficiency and functionality of the conveyor system.

Different Kinds of Non-Safe Interlocks

Non-safe interlocks can further be divided into three categories based on their operating principles.

1) Mechanical Interlock

Mechanical interlocks rely on physical mechanisms to control the conveyor system. For instance, a mechanical interlock might engage or disengage certain conveyor components based on the position of a lever or the presence of an object. This can help prevent jams and optimise material flow.

2) Electrical Interlock

Electrical interlocks use electrical signals and switches to control the conveyor’s operation. For example, a sensor can detect when a certain level of material has been reached on the conveyor, signalling the system to stop or start as needed. This precision helps in reducing waste and maintaining consistent production rates.

3) Logic Interlock

Logic interlocks are more advanced and often involve programmable logic controllers (PLCs). These controllers use software to make decisions based on various inputs, such as sensor data and operator commands. This level of automation can significantly enhance the efficiency and responsiveness of conveyor systems.

What is interlock Conveyor?

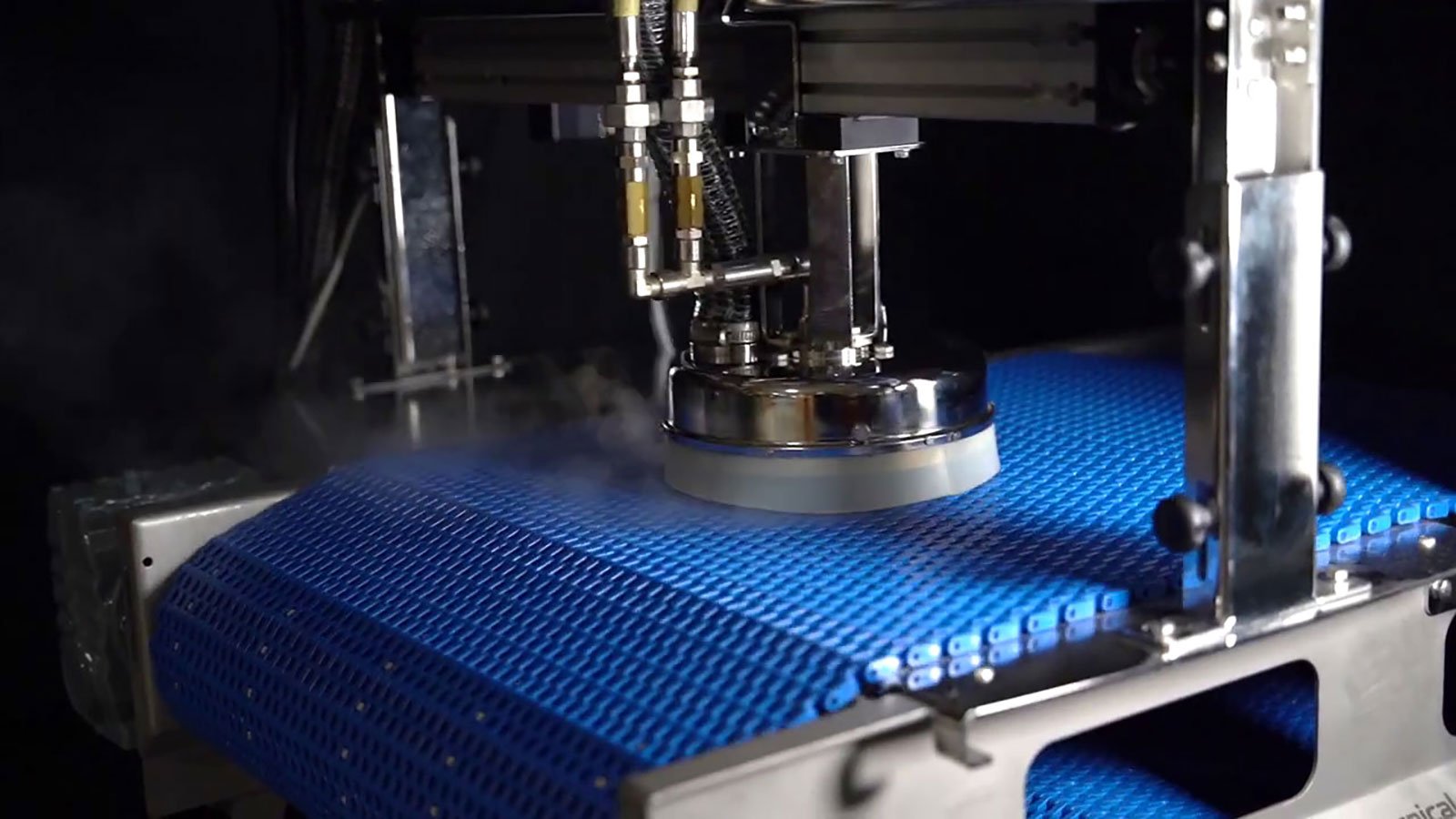

As we explore the world of interlock conveyor belts, it’s impossible not to mention the well-known Intralox conveyor systems. Intralox is a leading manufacturer of modular plastic conveyor belts, and their innovative solutions have gained widespread popularity in various industries.

Intralox conveyor systems are constructed using interconnected modules that form a continuous surface. These belt conveyors are known for their durability, ease of maintenance, and ability to handle a wide range of product sizes and shapes. They are particularly valued in industries such as food processing, automotive, and logistics.

What Does Intralox Do?

Intralox belt conveyor systems excel in several key areas that make them a preferred choice for many companies:

1. Enhanced Sanitation:

Intralox belts are designed with food safety in mind. They are easy to clean and sanitise, reducing the risk of contamination in food processing facilities. This is crucial for complying with strict hygiene regulations and ensuring product quality.

2. Reduced Downtime:

The modular nature of Intralox belts makes maintenance and repairs a breeze. When a section of the belt needs attention, it can be easily replaced without disrupting the entire production line. This results in reduced downtime and increased productivity.

3. Customisability:

Intralox offers a wide range of belt styles and configurations to meet the specific needs of different industries. Whether you require a straight conveyor, a spiral conveyor, or a belt with specialised features, Intralox can deliver a tailored solution.

4. Sustainability:

Sustainability is a growing concern for many companies. Intralox’s efficient conveyor systems

contribute to sustainability efforts by reducing energy consumption and waste generation. Their belts are also made from recyclable materials, aligning with environmental and sustainability goals.

Conclusion

In the world of industrial and manufacturing operations, efficiency, safety, and sustainability are paramount. Interlock conveyor belts, including those offered by industry leaders like Intralox, are at the forefront of innovation, helping companies achieve these goals. Whether you’re a Maintenance and Facilities Manager, Safety and Compliance Officer, Logistics and Supply Chain Professional, or Environmental and Sustainability Manager, incorporating an interlock conveyor belt into your operations can lead to significant improvements.

So, if you’re looking to take your manufacturing processes to the next level, consider the benefits of interlock belts and the cutting-edge solutions offered by companies like ConveyorCleaning.com.au. With their expertise and innovative products, you can streamline your operations, enhance safety, and contribute to a more sustainable future.

References:

ConveyorCleaning.com.au – Interlock Modular Conveyor Belt Cleaning