Conveyor belt cleaners are crucial for the smooth and efficient operation of conveyor systems across various industries. These devices are designed to remove carryback, which is material that adheres to the belt and can cause problems such as belt mistracking, spillage and increased maintenance costs. By effectively removing carryback, Conveyor Belt Cleaners help maintain belt integrity, improve overall system efficiency and reduce the risk of costly downtime.

Efficient conveyor belt cleaners contribute to a safer working environment by reducing the potential for slip and fall accidents caused by material accumulation on the belt. Moreover, by preventing material spillage, these cleaners help minimise the environmental impact of operations, ensuring compliance with regulations and reducing the risk of fines or penalties. The importance of conveyor belt cleaners is significant, as they are essential for maintaining productivity, safety and environmental responsibility of conveyor systems in numerous industries.

These cleaners are a vital component of any conveyor system, playing a critical role in ensuring smooth and efficient operation. By effectively removing carryback, they help prevent issues such as belt mistracking, material spillage and increased maintenance costs. In addition to improving system efficiency and reducing downtime, efficient conveyor belt cleaners contribute to a safer working environment by minimising the potential for slip and fall accidents caused by material buildup on the belt.

Furthermore, by preventing material spillage, they help minimise the environmental impact of operations, ensuring compliance with regulations and reducing the risk of fines or penalties. The importance of conveyor belt cleaners cannot be overstated, as they are essential for maintaining the productivity, safety and environmental responsibility of conveyor systems in a wide range of industries.

Summary

- Proper conveyor belt cleaners are essential for maintaining a safe and efficient working environment

- Efficient conveyor belt cleaners can improve material handling operations and reduce downtime

- Choosing the right conveyor belt cleaner for your facility is crucial for optimal performance

- Efficient conveyor belt cleaners can significantly reduce maintenance costs and increase equipment lifespan

- Using efficient conveyor belt cleaners can lead to environmental benefits such as reduced energy consumption and waste production

How an Efficient Conveyor Belt Cleaner Improves Operations

Improved System Efficiency

In addition to improving system efficiency, efficient conveyor belt cleaners also contribute to cost savings by reducing maintenance requirements and prolonging the life of the conveyor belt. By preventing material buildup and spillage, these cleaners help to minimise wear and tear on the belt and other components of the conveyor system, reducing the need for frequent repairs and replacements. This not only saves on maintenance costs but also extends the lifespan of the equipment, providing long-term cost benefits for the facility.

Reduced Downtime and Maintenance

By keeping the conveyor belt clean and free from carryback, efficient cleaners help to maintain proper belt alignment and reduce the risk of costly downtime caused by belt damage or mistracking. This, in turn, leads to improved system efficiency and productivity, as the conveyor can operate smoothly without interruptions.

Long-term Cost Benefits

In addition to improving system efficiency, efficient conveyor belt cleaners also contribute to cost savings by reducing maintenance requirements and prolonging the life of the conveyor belt. By preventing material buildup and spillage, these cleaners help to minimise wear and tear on the belt and other components of the conveyor system, reducing the need for frequent repairs and replacements. This not only saves on maintenance costs but also extends the lifespan of the equipment, providing long-term cost benefits for the facility.

Choosing the Right Conveyor Belt Cleaner for Your Facility

When selecting a conveyor belt cleaner for your facility, it is important to consider factors such as the type of material being conveyed, the operating conditions, and the specific requirements of your application. Different types of conveyor belt cleaners are available, each designed for specific cleaning needs and operating environments. For example, primary cleaners are typically used at the head pulley to remove large amounts of carryback, while secondary cleaners are installed further along the belt to provide additional cleaning and ensure that no carryback is left on the belt.

In addition to considering the type of cleaner, it is important to choose a cleaner that is compatible with your specific conveyor system and can effectively remove carryback without causing damage to the belt or other components. Factors such as blade material, tensioning mechanism, and mounting options should be carefully evaluated to ensure that the chosen cleaner meets your cleaning requirements while minimising maintenance needs and maximising operational efficiency. When selecting a conveyor belt cleaner for your facility, it is important to consider factors such as the type of material being conveyed, the operating conditions, and the specific requirements of your application.

Different types of conveyor belt cleaners are available, each designed for specific cleaning needs and operating environments. For example, primary cleaners are typically used at the head pulley to remove large amounts of carryback, while secondary cleaners are installed further along the belt to provide additional cleaning and ensure that no carryback is left on the belt. In addition to considering the type of cleaner, it is important to choose a cleaner that is compatible with your specific conveyor system and can effectively remove carryback without causing damage to the belt or other components.

Factors such as blade material, tensioning mechanism, and mounting options should be carefully evaluated to ensure that the chosen cleaner meets your cleaning requirements while minimising maintenance needs and maximising operational efficiency.

The Impact of Efficient Conveyor Belt Cleaners on Maintenance Costs

| Metrics | Before Efficient Cleaners | After Efficient Cleaners |

|---|---|---|

| Labour Costs | High | Reduced |

| Downtime | Frequent | Minimised |

| Conveyor Belt Lifespan | Shortened | Extended |

| Maintenance Frequency | Frequent | Reduced |

Efficient conveyor belt cleaners can have a significant impact on maintenance costs by reducing wear and tear on the conveyor belt and other system components. By effectively removing carryback and preventing material buildup and spillage, these cleaners help to minimise abrasion and damage to the belt, extending its lifespan and reducing the need for frequent replacements. This not only saves on replacement costs but also reduces downtime associated with belt maintenance, leading to further cost savings for the facility.

In addition to reducing wear on the conveyor belt, efficient cleaners also contribute to lower maintenance costs by minimising the need for manual cleaning and other maintenance activities. By keeping the belt clean and free from carryback, these cleaners help to reduce labour requirements for cleaning and maintenance tasks, allowing personnel to focus on other critical aspects of operations. This not only saves on labour costs but also improves overall operational efficiency by minimising downtime associated with maintenance activities.

Efficient conveyor belt cleaners can have a significant impact on maintenance costs by reducing wear and tear on the conveyor belt and other system components. By effectively removing carryback and preventing material buildup and spillage, these cleaners help to minimise abrasion and damage to the belt, extending its lifespan and reducing the need for frequent replacements. This not only saves on replacement costs but also reduces downtime associated with belt maintenance, leading to further cost savings for the facility.

In addition to reducing wear on the conveyor belt, efficient cleaners also contribute to lower maintenance costs by minimising the need for manual cleaning and other maintenance activities. By keeping the belt clean and free from carryback, these cleaners help to reduce labour requirements for cleaning and maintenance tasks, allowing personnel to focus on other critical aspects of operations. This not only saves on labour costs but also improves overall operational efficiency by minimising downtime associated with maintenance activities.

Environmental Benefits of Using Efficient Conveyor Belt Cleaners

In addition to improving operational efficiency and reducing maintenance costs, efficient conveyor belt cleaners also offer environmental benefits by minimising material spillage and reducing energy consumption. By preventing material buildup on the belt and spillage from occurring during operation, these cleaners help to minimise waste and reduce environmental impact. This not only contributes to a cleaner working environment but also ensures compliance with environmental regulations and reduces the risk of fines or penalties for non-compliance.

Furthermore, efficient conveyor belt cleaners can help to reduce energy consumption by improving system efficiency and reducing friction between the belt and pulleys. By keeping the belt clean and free from carryback, these cleaners help to maintain proper belt alignment and reduce resistance during operation, leading to lower energy requirements for running the conveyor system. This not only saves on energy costs but also contributes to overall sustainability efforts by minimising energy consumption and reducing carbon emissions.

In addition to improving operational efficiency and reducing maintenance costs, efficient conveyor belt cleaners also offer environmental benefits by minimising material spillage and reducing energy consumption. By preventing material buildup on the belt and spillage from occurring during operation, these cleaners help to minimise waste and reduce environmental impact. This not only contributes to a cleaner working environment but also ensures compliance with environmental regulations and reduces the risk of fines or penalties for non-compliance.

Furthermore, efficient conveyor belt cleaners can help to reduce energy consumption by improving system efficiency and reducing friction between the belt and pulleys. By keeping the belt clean and free from carryback, these cleaners help to maintain proper belt alignment and reduce resistance during operation, leading to lower energy requirements for running the conveyor system. This not only saves on energy costs but also contributes to overall sustainability efforts by minimising energy consumption and reducing carbon emissions.

Case Studies: Successful Implementation of Efficient Conveyor Belt Cleaners

Improved Operational Efficiency and Cost Savings

Several case studies have demonstrated the successful implementation of efficient conveyor belt cleaners in various industries, highlighting their positive impact on operational efficiency, maintenance costs, and environmental responsibility. For example, a mining company implemented a new primary cleaner at the head pulley of their conveyor system, resulting in a significant reduction in carryback and material spillage. This led to improved system efficiency, reduced downtime for maintenance activities, and substantial cost savings due to lower wear on the conveyor belt.

Enhanced Working Environments and Reduced Labour Requirements

Similarly, a manufacturing facility installed secondary cleaners along their conveyor belts to provide additional cleaning beyond what was achieved with primary cleaners alone. This resulted in a cleaner working environment with minimal material spillage, reduced labour requirements for manual cleaning tasks, and improved overall operational efficiency.

Industry-Wide Benefits and Environmental Responsibility

These case studies demonstrate how efficient conveyor belt cleaners can make a positive impact on various aspects of operations across different industries. By reducing carryback and material spillage, conveyor belt cleaners can help organisations reduce their environmental footprint and improve their overall operational efficiency.

Tips for Maintaining and Maximising the Efficiency of Conveyor Belt Cleaners

To ensure that conveyor belt cleaners continue to operate efficiently and effectively over time, it is important to implement regular maintenance practices that keep them in optimal condition. This includes inspecting blades for wear or damage regularly and replacing them when necessary to maintain proper cleaning performance. Additionally, adjusting blade pressure according to changing operating conditions can help maximise cleaning effectiveness while minimising wear on both blades and belts.

Furthermore, it is important to keep an eye on tensioning systems to ensure that blades are properly tensioned against the belt for effective cleaning without causing excessive wear or damage. Regularly monitoring cleaner performance through visual inspections or using monitoring systems can help identify any issues early on before they escalate into larger problems that could affect overall system efficiency. To ensure that conveyor belt cleaners continue to operate efficiently and effectively over time, it is important to implement regular maintenance practices that keep them in optimal condition.

This includes inspecting blades for wear or damage regularly and replacing them when necessary to maintain proper cleaning performance. Additionally, adjusting blade pressure according to changing operating conditions can help maximise cleaning effectiveness while minimising wear on both blades and belts. Furthermore, it is important to keep an eye on tensioning systems to ensure that blades are properly tensioned against the belt for effective cleaning without causing excessive wear or damage.

Regularly monitoring cleaner performance through visual inspections or using monitoring systems can help identify any issues early on before they escalate into larger problems that could affect overall system efficiency. In conclusion, Conveyor belt cleaners play a crucial role in maintaining operational efficiency, reducing maintenance costs, ensuring environmental responsibility in various industries. Efficient conveyor belt cleaners effectively remove carryback from belts which prevents issues such as mistracking or spillage that could lead to costly downtime or accidents in workplaces due to slip hazards caused by material buildup on belts.

Choosing an appropriate cleaner based on specific needs is crucial as different types are available depending on factors such as material being conveyed or operating conditions which could affect its effectiveness in maintaining cleanliness without causing damage or excessive wear on belts or other components. Efficient conveyer belts have been proven through case studies in various industries such as mining or manufacturing where they have led to significant improvements in operational efficiency through reduced downtime due to maintenance activities or cost savings from lower wear on belts. Regular maintenance practices such as inspecting blades for wear or damage regularly or adjusting blade pressure according to changing operating conditions are essential in ensuring that conveyer belts continue operating efficiently over time without causing excessive wear or damage while maximising their effectiveness in maintaining cleanliness without causing excessive wear or damage.

Overall conveyer belts play an essential role in maintaining operational efficiency while ensuring environmental responsibility through their ability in preventing material spillage which could lead to waste production or energy consumption through improved system efficiency which reduces friction between belts leading lower energy requirements for running conveyer systems which contributes towards overall sustainability efforts through minimising energy consumption while reducing carbon emissions.

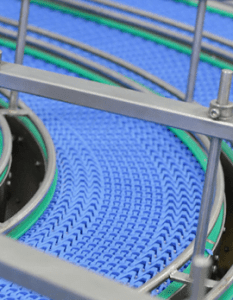

If you are interested in learning more about the future of manufacturing efficiency, you should check out this article on interlock conveyor belts. This article discusses how interlock conveyor belts are revolutionising the manufacturing industry and improving efficiency. It provides valuable insights into the benefits of using interlock conveyor belts and how they can streamline production processes.

FAQs

What is a conveyor belt cleaner?

A conveyor belt cleaner is a device used to remove material adhering to the surface of a conveyor belt. It is essential for maintaining the efficiency and longevity of the conveyor system.

Why is a conveyor belt cleaner important?

A conveyor belt cleaner is important because it helps to prevent material buildup on the conveyor belt, which can lead to increased wear and tear, reduced efficiency, and potential damage to the conveyor system.

How does a conveyor belt cleaner work?

A conveyor belt cleaner typically uses a blade or brush to remove material from the surface of the conveyor belt as it passes through the cleaner. This helps to keep the belt clean and free from debris.

What are the different types of conveyor belt cleaners?

There are several types of conveyor belt cleaners, including primary cleaners, secondary cleaners, and specialty cleaners. Primary cleaners are located at the head pulley and are designed to remove the bulk of the material from the belt. Secondary cleaners are located further along the belt and are used to remove any remaining material. Specialty cleaners are designed for specific applications, such as high-temperature or corrosive environments.

How do I choose the right conveyor belt cleaner for my application?

When choosing a conveyor belt cleaner, it is important to consider factors such as the type of material being conveyed, the speed and load of the conveyor system, and any specific environmental conditions. It is also important to consider the maintenance requirements and the overall cost of the cleaner. Consulting with a professional in the field can help in selecting the right conveyor belt cleaner for a specific application.