Introduction

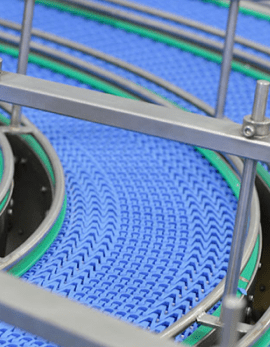

In industrial settings, maintaining cleanliness and hygiene is crucial, especially for conveyor belts. Conveyor belt cleaning brushes play a vital role in preventing debris, residue, and contaminants from affecting product quality and safety. However, selecting the appropriate brushes for your specific sector can be challenging. This article provides guidance on choosing the right cleaning brushes based on industry needs.

1. Understand Your Sector’s Requirements:

Evaluate the cleaning needs of your sector, considering factors such as conveyor belt material, type of debris or residue, and required cleaning frequency. Tailor your brush selection to address these specific requirements, such as using brushes with suitable bristle materials or configurations for fine particles or adhesive substances.

2. Consider Brush Material and Design:

Choose brush materials that offer durability and abrasion resistance, such as nylon, polypropylene, or stainless steel. Additionally, consider brush design elements like bristle length, density, and stiffness to ensure effective cleaning without damaging the belt.

3. Evaluate Cleaning Methodologies:

Assess different cleaning methodologies available for your conveyor system, such as rotary, oscillating, or stationary brushes. Understand the advantages and disadvantages of each method to select the most suitable option for your sector’s needs.

4. Ensure Compatibility with Your Conveyor System:

Ensure that the chosen conveyor belt cleaning brushes are compatible with your conveyor system. Consider factors like brush size, mounting options, and ease of installation. Seamless integration of the brushes into your system maximises efficiency while minimising disruptions during installation.

5. Prioritise Safety and Hygiene:

Choose brushes that are easy to clean, sanitise, and maintain, prioritising safety and hygiene. Look for brushes that comply with industry regulations or are approved by relevant organizations like the Food Standards Australia New Zealand (FSANZ) to ensure food safety and product integrity.

6. Conclusion:

Selecting the right conveyor belt cleaning brushes for your sector is essential for maintaining cleanliness, productivity, and product quality. By understanding sector-specific requirements, considering brush materials and designs, evaluating cleaning methodologies, ensuring compatibility, and prioritising safety and hygiene, you can make informed decisions that contribute to a safer and more hygienic working environment.