Conveyor belt cleaning systems are an essential component of any industrial operation utilising conveyor belts. These systems are engineered to remove debris, spillage and other contaminants from the conveyor belt surface, ensuring smooth and efficient operation. Proper cleaning of conveyor belts is crucial for maintaining belt integrity and ensuring the safety of workers and transported products.

Various types of conveyor belt cleaning systems are available, each with distinct features and benefits. This article will examine the different types of conveyor belt cleaning systems, the importance of proper cleaning, factors to consider when selecting a cleaning system, maintenance and troubleshooting advice, as well as the advantages of employing effective cleaning systems.

Summary

- Conveyor belt cleaning systems are essential for maintaining the efficiency and longevity of conveyor belts in various industries.

- There are different types of conveyor belt cleaning systems, including scrapers, brushes, and air knives, each with its own advantages and applications.

- Proper conveyor belt cleaning is important for preventing material carryback, reducing maintenance costs, and ensuring a safe working environment.

- When choosing a conveyor belt cleaning system, factors such as belt material, belt speed, and the type of material being conveyed should be taken into consideration.

- Regular maintenance and troubleshooting of conveyor belt cleaning systems are crucial for ensuring optimal performance and preventing costly downtime.

Types of Conveyor Belt Cleaning Systems

Mechanical Belt Scrapers

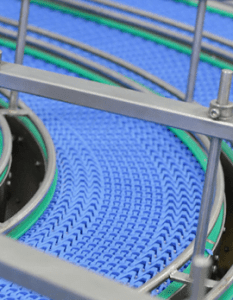

One common type is the mechanical belt scraper, which utilises a blade or brush to remove debris from the belt surface. These scrapers can be mounted on the head pulley, tail pulley, or along the belt itself, and are effective at removing large particles and spillage.

Alternative Cleaning Methods

Another type is the belt brush cleaner, which utilises rotating brushes to sweep debris off the belt surface. These brushes can be made from various materials such as nylon, polypropylene, or steel, depending on the specific cleaning requirements. Additionally, there are air knife systems that use compressed air to blow debris off the belt surface, as well as water-based cleaning systems that use high-pressure water jets to wash away contaminants.

Selecting the Right System

Each type of cleaning system has its own advantages and limitations, and the choice of system will depend on factors such as the type of material being transported, the level of contamination, and the operating environment.

Importance of Proper Conveyor Belt Cleaning

Proper conveyor belt cleaning is essential for maintaining the efficiency and safety of conveyor belt systems. When conveyor belts are not cleaned regularly, debris and spillage can accumulate on the belt surface, leading to increased friction and wear. This can result in premature belt failure, increased energy consumption, and costly downtime for repairs and replacements.

In addition, accumulated debris can also pose a safety hazard by causing slip and trip hazards for workers. Furthermore, in industries where hygiene is critical, such as food processing and pharmaceuticals, proper cleaning is essential for preventing contamination of products. By investing in effective conveyor belt cleaning systems, businesses can ensure the longevity of their conveyor belts, reduce maintenance costs, improve worker safety, and maintain product quality.

Factors to Consider When Choosing a Conveyor Belt Cleaning System

When choosing a conveyor belt cleaning system, there are several factors that need to be taken into consideration to ensure that the system meets the specific cleaning requirements of the operation. One important factor is the type of material being transported on the conveyor belt. For example, in industries where sticky or viscous materials are being transported, a mechanical scraper or brush cleaner may be more effective at removing the residue compared to an air knife system.

The level of contamination is another crucial factor to consider, as operations with heavy spillage may require a more robust cleaning system with higher cleaning power. Additionally, the operating environment, such as temperature, humidity, and presence of water or chemicals, will also influence the choice of cleaning system. It is important to work with a knowledgeable supplier who can assess these factors and recommend a suitable cleaning system that meets the specific needs of the operation.

Maintenance and Troubleshooting of Conveyor Belt Cleaning Systems

Proper maintenance and troubleshooting of conveyor belt cleaning systems are essential for ensuring their continued effectiveness and longevity. Regular inspection of the cleaning system components such as blades, brushes, or air knives is important to identify any signs of wear or damage that may affect their performance. It is also important to ensure that the cleaning system is properly adjusted to maintain the optimal contact with the belt surface without causing excessive wear.

In addition, regular cleaning and lubrication of moving parts will help prevent premature failure and ensure smooth operation. Troubleshooting issues such as excessive belt wear, ineffective cleaning, or unusual noise should be addressed promptly to prevent further damage to the conveyor belt and the cleaning system. By implementing a proactive maintenance and troubleshooting plan, businesses can minimise downtime and reduce overall maintenance costs.

Advantages of Using Effective Conveyor Belt Cleaning Systems

Maintenance and Cost Savings

These systems help to maintain the integrity and longevity of conveyor belts by preventing excessive wear and damage caused by debris and spillage. This ultimately reduces maintenance costs and downtime for repairs and replacements.

Improved Worker Safety

Effective cleaning systems contribute to improved worker safety by reducing slip and trip hazards caused by accumulated debris on the belt surface. This is particularly important in industries where worker safety is a top priority. Additionally, in industries where hygiene is critical, such as food processing and pharmaceuticals, effective cleaning systems help to prevent contamination of products by removing debris and spillage from the belt surface.

Operational Efficiency

Furthermore, by maintaining clean conveyor belts, businesses can improve operational efficiency by reducing energy consumption and ensuring smooth material flow.

Conclusion and Future Developments in Conveyor Belt Cleaning Systems

In conclusion, proper conveyor belt cleaning is essential for maintaining the efficiency, safety, and hygiene of industrial operations that utilise conveyor belts. There are various types of conveyor belt cleaning systems available, each with its own unique features and benefits. When choosing a cleaning system, it is important to consider factors such as the type of material being transported, level of contamination, and operating environment to ensure that the system meets the specific cleaning requirements of the operation.

Proper maintenance and troubleshooting of cleaning systems are crucial for ensuring their continued effectiveness and longevity. Looking ahead, future developments in conveyor belt cleaning systems may focus on improving automation and efficiency through the use of advanced technologies such as sensors and monitoring systems. These developments may enable real-time monitoring of cleaning system performance and predictive maintenance to prevent unexpected failures.

Additionally, advancements in materials and design may lead to more durable and effective cleaning components that can withstand harsh operating conditions. By embracing these future developments, businesses can further enhance the effectiveness of their conveyor belt cleaning systems and improve overall operational efficiency.

FAQs

What are conveyor belt cleaning systems?

Conveyor belt cleaning systems are devices or mechanisms used to remove debris, spillage, and other materials from conveyor belts to ensure efficient and safe operation.

Why are conveyor belt cleaning systems important?

Conveyor belt cleaning systems are important for maintaining the efficiency and longevity of conveyor belts. They help prevent material buildup, reduce the risk of belt damage, and ensure a clean working environment.

What are the common types of conveyor belt cleaning systems?

Common types of conveyor belt cleaning systems include belt scrapers, belt brushes, belt washers, and air knife systems. Each type is designed to address specific cleaning needs based on the type of material being conveyed and the operating environment.

How do conveyor belt cleaning systems work?

Conveyor belt cleaning systems work by removing debris and spillage from the conveyor belt surface. This can be achieved through mechanical scraping, brushing, washing, or using compressed air to dislodge and remove materials.

What are the benefits of using conveyor belt cleaning systems?

The benefits of using conveyor belt cleaning systems include improved belt performance, reduced maintenance costs, increased operational efficiency, and a safer working environment. These systems also help to comply with industry regulations and standards.

How do I choose the right conveyor belt cleaning system for my application?

When choosing a conveyor belt cleaning system, factors to consider include the type of material being conveyed, the operating environment, belt speed, and the specific cleaning requirements. It is important to consult with a professional to determine the most suitable system for your application.