Conveyor belt brushes play a crucial role in the efficient operation of conveyor systems across various industries. These brushes are designed to clean conveyor belts, remove debris, and prevent material build-up, ensuring smooth and uninterrupted material flow. By effectively removing carryback and preventing material spillage, conveyor belt brushes help to improve productivity, reduce maintenance costs, and enhance workplace safety.

Additionally, they contribute to the overall cleanliness of the production environment, which is essential for maintaining high standards of hygiene and compliance with industry regulations. Conveyor belt brushes are particularly important in industries such as food processing, pharmaceuticals, and manufacturing, where cleanliness and sanitation are paramount. In these environments, any contamination or build-up on the conveyor belt can compromise product quality and safety.

By utilising conveyor belt brushes, companies can ensure that their production processes remain efficient, hygienic, and compliant with industry standards. Furthermore, conveyor belt brushes also help to extend the lifespan of conveyor belts by reducing wear and tear caused by material build-up and friction. These essential components of conveyor systems play a vital role in ensuring the smooth and efficient operation of conveyor belts by removing debris, preventing material build-up, and reducing carryback.

In addition to improving productivity and reducing maintenance costs, conveyor belt brushes also contribute to the overall cleanliness and hygiene of the production environment. This is particularly important in industries such as food processing and pharmaceuticals, where product quality and safety are of utmost importance. By employing conveyor belt brushes, companies can ensure that their production processes remain efficient, hygienic, and compliant with industry regulations.

The importance of conveyor belt brushes in maintaining the efficiency, cleanliness, and safety of conveyor systems is undeniable.

Summary

- Conveyor belt brushes are essential for maintaining the cleanliness and efficiency of conveyor systems in various industries.

- There are different types of conveyor belt brushes, including spiral, strip, and rotary brushes, each with specific applications in cleaning, sealing, and polishing.

- When choosing a conveyor belt brush, it is important to consider factors such as belt material, speed, and the type of debris or material being transported.

- Proper installation and regular maintenance of conveyor belt brushes are crucial for ensuring optimal performance and longevity of the brushes and conveyor system.

- Using conveyor belt brushes can lead to benefits such as improved product quality, reduced maintenance costs, and increased workplace safety.

Types of Conveyor Belt Brushes and Their Applications

Common Types of Conveyor Belt Brushes

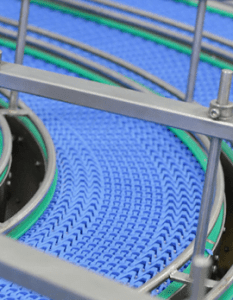

The most common types of conveyor belt brushes include spiral brush rollers, strip brush cleaners, rotary brush cleaners, and paddle wheel brush cleaners. Spiral brush rollers are ideal for cleaning flat or cleated conveyor belts and are effective in removing fine particles and debris. Strip brush cleaners are suitable for light-duty applications and are often used to remove loose materials from conveyor belts. Rotary brush cleaners are designed for heavy-duty applications and can effectively remove stubborn debris and carryback from conveyor belts. Paddle wheel brush cleaners are ideal for cleaning large volumes of material from conveyor belts and are commonly used in industries such as mining and aggregates.

Factors to Consider When Choosing a Conveyor Belt Brush

The choice of conveyor belt brush depends on factors such as the type of material being conveyed, the operating environment, and the specific cleaning requirements. For example, in industries where hygiene is critical, such as food processing and pharmaceuticals, spiral brush rollers or rotary brush cleaners may be preferred for their ability to effectively remove fine particles and stubborn debris. On the other hand, in heavy-duty applications such as mining and aggregates, paddle wheel brush cleaners may be more suitable for their ability to handle large volumes of material.

Importance of Selecting the Right Conveyor Belt Brush

Ultimately, selecting the right type of conveyor belt brush is essential for ensuring effective cleaning and maintenance of conveyor belts in various industrial applications.

Choosing the Right Conveyor Belt Brush for Your Application

When choosing a conveyor belt brush for a specific application, it is important to consider several factors to ensure that the brush meets the cleaning requirements and operating conditions. The type of material being conveyed is a crucial consideration when selecting a conveyor belt brush. For example, in industries where fine particles or sticky materials are being conveyed, a brush with soft bristles or spiral brush rollers may be more effective in removing debris from the conveyor belt.

Similarly, in heavy-duty applications where large volumes of material need to be cleaned from the belt, a paddle wheel brush cleaner may be more suitable due to its ability to handle high material loads. The operating environment also plays a significant role in determining the right conveyor belt brush for a specific application. For example, in environments with high humidity or moisture levels, it is important to choose a brush that is resistant to corrosion and can withstand harsh conditions.

Additionally, factors such as temperature extremes, abrasive materials, and chemical exposure should also be taken into account when selecting a conveyor belt brush. By considering these factors and understanding the specific cleaning requirements of the application, companies can choose the right conveyor belt brush that will effectively clean the conveyor belt and ensure smooth material flow. When choosing a conveyor belt brush for a specific application, it is important to consider several factors to ensure that the brush meets the cleaning requirements and operating conditions.

The type of material being conveyed is a crucial consideration when selecting a conveyor belt brush. For example, in industries where fine particles or sticky materials are being conveyed, a brush with soft bristles or spiral brush rollers may be more effective in removing debris from the conveyor belt. Similarly, in heavy-duty applications where large volumes of material need to be cleaned from the belt, a paddle wheel brush cleaner may be more suitable due to its ability to handle high material loads.

The operating environment also plays a significant role in determining the right conveyor belt brush for a specific application. For example, in environments with high humidity or moisture levels, it is important to choose a brush that is resistant to corrosion and can withstand harsh conditions. Additionally, factors such as temperature extremes, abrasive materials, and chemical exposure should also be taken into account when selecting a conveyor belt brush.

By considering these factors and understanding the specific cleaning requirements of the application, companies can choose the right conveyor belt brush that will effectively clean the conveyor belt and ensure smooth material flow.

Installation and Maintenance of Conveyor Belt Brushes

Proper installation and maintenance of conveyor belt brushes are essential for ensuring their effectiveness in cleaning conveyor belts and preventing material buildup. During installation, it is important to ensure that the brush is positioned at the correct angle and pressure against the conveyor belt to achieve optimal cleaning performance. Additionally, regular inspection and maintenance of the brushes are necessary to ensure that they remain in good working condition.

This includes checking for wear on the bristles, adjusting the pressure settings if necessary, and replacing any damaged or worn-out parts. In addition to regular maintenance, it is also important to clean the brushes themselves to prevent them from becoming clogged with debris or material buildup. This can be done using compressed air or water to remove any accumulated debris from the bristles.

Proper maintenance of conveyor belt brushes not only ensures their effectiveness in cleaning the conveyor belts but also helps to extend their lifespan and reduce maintenance costs in the long run. Proper installation and maintenance of conveyor belt brushes are essential for ensuring their effectiveness in cleaning conveyor belts and preventing material buildup. During installation, it is important to ensure that the brush is positioned at the correct angle and pressure against the conveyor belt to achieve optimal cleaning performance.

Additionally, regular inspection and maintenance of the brushes are necessary to ensure that they remain in good working condition. This includes checking for wear on the bristles, adjusting the pressure settings if necessary, and replacing any damaged or worn-out parts. In addition to regular maintenance, it is also important to clean the brushes themselves to prevent them from becoming clogged with debris or material buildup.

This can be done using compressed air or water to remove any accumulated debris from the bristles. Proper maintenance of conveyor belt brushes not only ensures their effectiveness in cleaning the conveyor belts but also helps to extend their lifespan and reduce maintenance costs in the long run.

Benefits of Using Conveyor Belt Brushes

The use of conveyor belt brushes offers several benefits for companies across various industries. One of the primary benefits is improved productivity through reduced downtime caused by material buildup on conveyor belts. By effectively removing carryback and preventing material spillage, conveyor belt brushes help to maintain smooth material flow and prevent blockages that can disrupt production processes.

This ultimately leads to increased operational efficiency and reduced maintenance costs associated with cleaning up material spillage. In addition to improving productivity, using conveyor belt brushes also contributes to workplace safety by reducing slip hazards caused by material buildup on conveyor belts. By keeping the belts clean and free from debris, companies can create a safer working environment for their employees while also reducing the risk of accidents and injuries.

Furthermore, by preventing material buildup on conveyor belts, companies can also extend the lifespan of their equipment and reduce maintenance costs over time. The use of conveyor belt brushes offers several benefits for companies across various industries. One of the primary benefits is improved productivity through reduced downtime caused by material buildup on conveyor belts.

By effectively removing carryback and preventing material spillage, conveyor belt brushes help to maintain smooth material flow and prevent blockages that can disrupt production processes. This ultimately leads to increased operational efficiency and reduced maintenance costs associated with cleaning up material spillage. In addition to improving productivity, using conveyor belt brushes also contributes to workplace safety by reducing slip hazards caused by material buildup on conveyor belts.

By keeping the belts clean and free from debris, companies can create a safer working environment for their employees while also reducing the risk of accidents and injuries. Furthermore, by preventing material buildup on conveyor belts, companies can also extend the lifespan of their equipment and reduce maintenance costs over time.

Safety Considerations When Using Conveyor Belt Brushes

Safety Training for Employees

Proper training should be provided to employees who will be working with or around conveyor belt brushes to ensure that they understand how to operate them safely and avoid potential hazards. This includes understanding how to adjust pressure settings on the brushes without risking injury or damage to equipment.

Regular Inspection and Maintenance

In addition to training employees on safe operation practices, it is also important to regularly inspect and maintain conveyor belt brushes to ensure that they remain in good working condition. This includes checking for wear on bristles or any signs of damage that could compromise their effectiveness or pose safety risks.

Creating a Safer Working Environment

By prioritising safety considerations when using conveyor belt brushes, companies can create a safer working environment for their employees while maximising the benefits of these devices for improving productivity and cleanliness.

Innovations and Future Trends in Conveyor Belt Brushes

As technology continues to advance, there are several innovations and future trends emerging in the field of conveyor belt brushes that aim to further improve their effectiveness and efficiency. One such trend is the development of automated cleaning systems that use sensors to detect material buildup on conveyor belts and activate the brushes as needed. This not only reduces manual intervention but also ensures that cleaning is performed at optimal times without disrupting production processes.

Another innovation in conveyor belt brushes is the use of advanced materials for bristles that offer improved durability and cleaning performance. For example, some manufacturers are developing bristles made from high-performance polymers or composite materials that offer superior wear resistance and cleaning efficiency compared to traditional bristle materials. Furthermore, advancements in robotics technology are also being integrated into conveyor belt cleaning systems to automate maintenance tasks such as adjusting pressure settings or replacing worn-out parts on the brushes.

These innovations not only improve efficiency but also reduce labour costs associated with manual maintenance tasks. As technology continues to advance, there are several innovations and future trends emerging in the field of conveyor belt brushes that aim to further improve their effectiveness and efficiency. One such trend is the development of automated cleaning systems that use sensors to detect material buildup on conveyor belts and activate the brushes as needed.

This not only reduces manual intervention but also ensures that cleaning is performed at optimal times without disrupting production processes. Another innovation in conveyor belt brushes is the use of advanced materials for bristles that offer improved durability and cleaning performance. For example, some manufacturers are developing bristles made from high-performance polymers or composite materials that offer superior wear resistance and cleaning efficiency compared to traditional bristle materials.

Furthermore, advancements in robotics technology are also being integrated into conveyor belt cleaning systems to automate maintenance tasks such as adjusting pressure settings or replacing worn-out parts on the brushes. These innovations not only improve efficiency but also reduce labour costs associated with manual maintenance tasks. In conclusion, Conveyor belt brushes play a crucial role in maintaining efficient operations within various industries by ensuring smooth material flow through effective cleaning of conveyer belts while preventing carryback build-up which could lead to blockages or spillages which could disrupt production processes leading ultimately leading increased operational efficiency while reducing maintenance costs associated with cleaning up material spillage.

There are several types of conveyer belt brushes available each designed for specific applications including spiral brush rollers which are ideal for flat or cleated conveyer belts while strip brush cleaners are suitable for light-duty applications while rotary brush cleaners are designed for heavy-duty applications.

When choosing a conveyer belt brush it’s important consider

FAQs

What are conveyor belt brushes?

Conveyor belt brushes are devices used to clean conveyor belts in industrial settings. They are typically made of bristles or other materials and are mounted along the conveyor belt to remove debris, dirt, and other contaminants.

What are the benefits of using conveyor belt brushes?

Conveyor belt brushes help to maintain the cleanliness of the conveyor belt, which can improve overall efficiency and reduce the risk of contamination in the production process. They also help to extend the lifespan of the conveyor belt by preventing excessive wear and tear.

How do conveyor belt brushes work?

Conveyor belt brushes work by coming into contact with the surface of the conveyor belt as it moves. The bristles or other cleaning materials on the brushes dislodge and remove debris, dirt, and other contaminants from the belt, preventing them from accumulating and causing issues.

What are the different types of conveyor belt brushes?

There are various types of conveyor belt brushes available, including spiral brushes, strip brushes, rotary brushes, and paddle brushes. Each type is designed for specific applications and conveyor belt configurations.

How do I choose the right conveyor belt brush for my application?

When choosing a conveyor belt brush, factors to consider include the type of material being conveyed, the speed and size of the conveyor belt, the level of contamination, and the specific cleaning requirements of the application. It is advisable to consult with a professional to determine the most suitable brush for your needs.

How do I install and maintain conveyor belt brushes?

Conveyor belt brushes should be installed according to the manufacturer’s guidelines, ensuring proper alignment and contact with the conveyor belt. Regular maintenance, such as cleaning the brushes and inspecting for wear, is essential to ensure optimal performance and longevity.