Keeping your food-grade conveyor belt clean is paramount for ensuring food safety and maintaining the quality of your products. Here’s a step-by-step guide to help you clean your conveyor belt effectively:

1. Preparation

Gather Your Supplies:

- Food-safe cleaning solutions and sanitisers

- Scrub brushes, sponges, and non-abrasive pads

- Clean cloths and paper towels

- Personal protective equipment (PPE) like gloves and safety glasses

Turn Off and Unplug Equipment:

- Before you start, make sure the conveyor belt and any associated machinery are turned off and unplugged to prevent any accidents during the cleaning process.

2. Initial Cleaning

Remove Loose Debris:

- Use a dry brush or cloth to sweep away any loose debris, crumbs, and food particles from the conveyor belt. Pay special attention to the edges and crevices where debris tends to accumulate.

Disassemble Removable Parts:

- If your conveyor belt has parts that can be easily disassembled, take them apart to ensure a more thorough cleaning.

3. Cleaning Process

Apply Cleaning Solution:

- Choose a suitable food-safe cleaning solution and apply it evenly across the surface of the conveyor belt. Ensure all areas are covered.

Scrub the Belt:

- Use a scrub brush or sponge to thoroughly scrub the conveyor belt, focusing on areas with heavy residue or stains. Employ non-abrasive pads to avoid damaging the belt.

Rinse Thoroughly:

- Rinse the conveyor belt with clean, potable water to wash away the cleaning solution and any loosened debris. Make sure all cleaning agents are completely removed to prevent contamination.

4. Sanitising

Apply Sanitiser:

- After cleaning, apply a food-safe sanitiser to the conveyor belt. Follow the manufacturer’s instructions for the correct dilution and application method.

Allow to Air Dry:

- Let the conveyor belt air dry completely before reassembling and using it again. Avoid using towels or cloths that might introduce new contaminants.

5. Inspection and Reassembly

Inspect the Belt:

- Check the conveyor belt for any remaining debris, residue, or damage. Ensure it is thoroughly cleaned and sanitised.

Reassemble Parts:

- Reassemble any parts that were removed for cleaning, ensuring they are securely fitted and functional.

Perform a Final Check:

- Conduct a final inspection to ensure all safety measures are in place and the belt is ready for use.

6. Documentation and Maintenance

Record the Cleaning Process:

- Document the cleaning process, including the date and time it was performed. This helps maintain a cleaning schedule and ensures compliance with food safety regulations.

Regular Maintenance Schedule:

- Establish a regular cleaning and maintenance schedule to keep the conveyor belt clean and efficient. Frequent cleaning reduces the risk of contamination and prolongs the equipment’s lifespan.

Tips for Effective Cleaning

- Use Appropriate Cleaning Agents: Always use food-safe cleaning agents and sanitisers that are approved for use in food processing environments.

- Regular Inspections: Regularly inspect the conveyor belt for signs of wear and tear, which can harbour bacteria and contaminants.

- Train Staff: Ensure that all cleaning staff are trained in proper cleaning and sanitising techniques to maintain high hygiene standards.

Choosing the Right Cleaning Solution

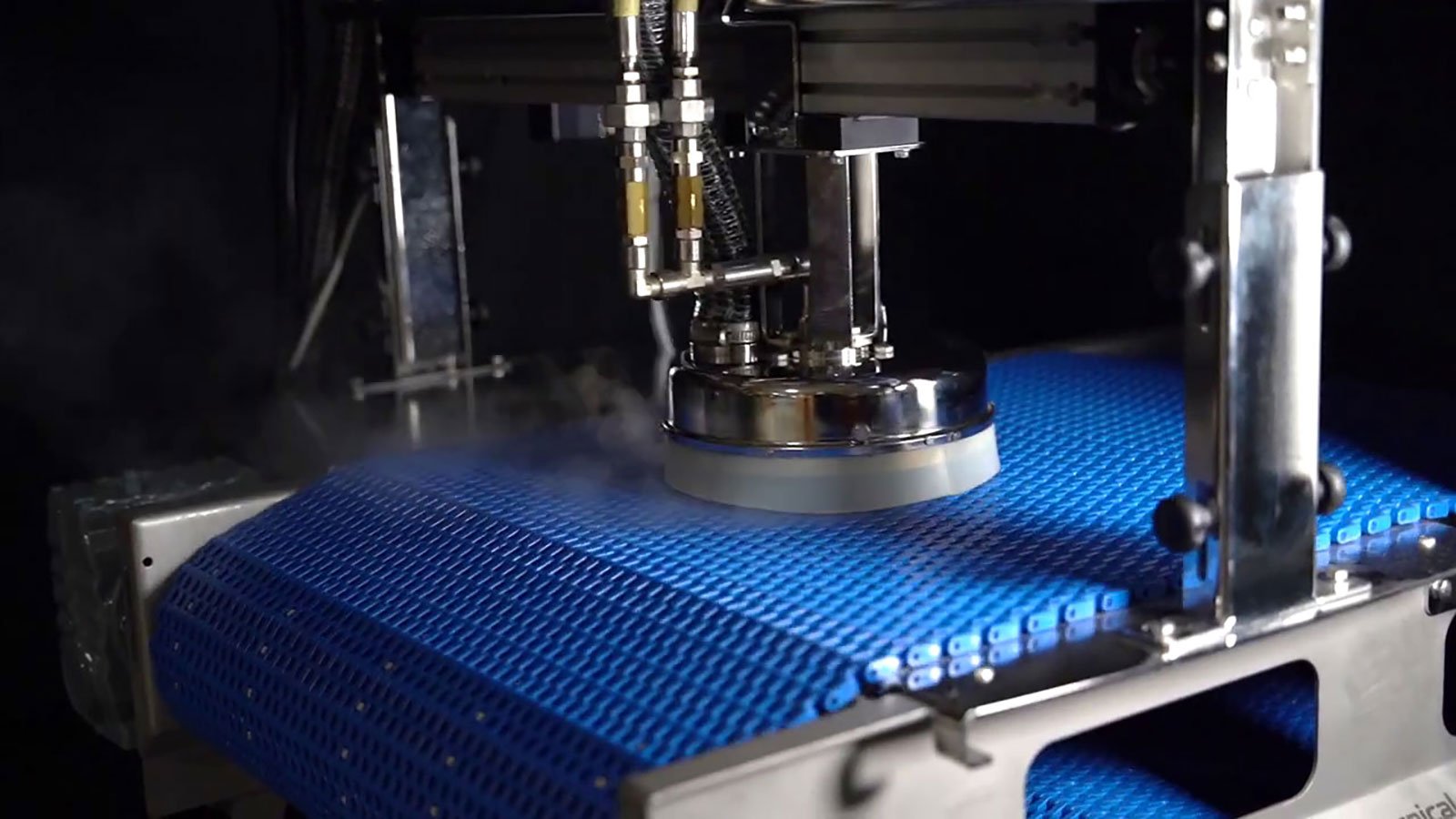

For a more specialised solution, you might want to look into products designed for continuous operation. These solutions can clean your conveyor belt while it’s still in operation, reducing downtime and maintaining hygiene standards. Check out Conveyor Cleaning for options tailored to your needs, including 24-hour operation cleaning solutions.

By following these steps and using the right products, you can ensure that your food-grade conveyor belt remains clean, safe, and efficient, ultimately protecting your products and your business.

Have you tried continuous operation cleaning solutions for your conveyor belts? Visit Conveyor Cleaning to explore options that keep your belts clean around the clock, including innovative steam cleaning systems that operate 24/7, ensuring minimal downtime and maximum efficiency.