Conveyor belts are the main character of industrial and manufacturing processes, ensuring the seamless flow of goods from one point to another. But, for these workhorses to perform at their best, they require regular maintenance and care. One often-overlooked yet vital aspect of this maintenance is cleaning underneath those belts. Whether you’re a maintenance and facilities manager, a safety and compliance officer, a logistics and supply chain professional, an environmental and sustainability manager, an engineering and equipment supplier, or a health and safety consultant, this article is your essential guide to mastering conveyor belt cleaning underneath for industrial excellence.

Understanding the Importance of Underneath Conveyor Belt Cleaning

Types of Conveyor Belt Cleaners

Before diving into the details of conveyor belt cleaning, let’s understand the various types of cleaners available. Each type serves a specific purpose and caters to different industries and applications.

Primary Belt Cleaners

Positioned beneath the head pulley, these are the first line of defence against material buildup on these belt conveyors.

Secondary Belt Cleaners

Located just after the primary cleaners, these ensure that any remaining material is thoroughly removed, preventing it from re-entering the conveyor system.

Heavy-Duty Belt Cleaners

In demanding industries like mining, heavy-duty cleaners are indispensable. They are robust and capable of handling the toughest cleaning challenges.

The Difference Between Cleaning, Sanitation, and Disinfection

It’s crucial to differentiate between cleaning, sanitation, and disinfection. These terms, though seemingly similar, have distinct meanings and implications.

Cleaning: Regular cleaning and appropriate commercial cleaning supplies can prevent corrosion on metal equipment, which can lead to costly repairs or replacements.

Sanitation: Sanitation goes beyond cleaning and involves the use of chemicals and cleaning agents to eliminate microorganisms and bacteria from beneath the belt. It’s vital in industries where hygiene is paramount, such as food processing.

Disinfection: Disinfection is the highest level of cleaning, aiming to eradicate all harmful microorganisms, including bacteria and viruses. It’s critical in industries where contamination can have severe consequences.

Risks of Neglecting Underneath Conveyor Belt Cleaning

Neglecting this can lead to various risks for industrial and manufacturing companies. Here are some of the potential consequences:

Reduced Efficiency: Accumulated debris beneath the belt can increase friction, causing wear and tear and reducing its lifespan. This results in frequent replacements and higher operational costs.

Contamination Hazards: In industries where hygiene is paramount, such as food processing, improper under-belt maintenance can lead to product contamination. This can result in costly recalls and damage to your brand’s reputation.

Safety Concerns: Debris and material buildup beneath the belt can create safety hazards for workers, leading to accidents and injuries. Maintaining a clean conveyor and everything underneath is essential for a safe working environment.

Key Considerations for Cleaning Underneath The Conveyor Belt

Now that we recognise the importance of cleaning underneath the belts, let’s explore essential considerations when implementing a cleaning and maintenance regimen:

Cleaning Frequency: A clean and well-maintained facility conveys that you care about your employees’ working conditions, boosting morale and job satisfaction.

Chemical Compatibility: Ensure that the cleaning agents and disinfectants you use are compatible with the materials of your belt. Using the wrong chemicals can lead to belt degradation.

Choosing the Right Cleaners: Select the appropriate type of belt cleaner for your specific application. Primary, secondary, and heavy-duty cleaners serve distinct roles and are tailored to different cleaning challenges.

Employee Training: Properly train your maintenance and operations staff in correct cleaning procedures, including safety protocols and the use of personal protective equipment (PPE).

Regular Inspections: Implement routine inspections to identify signs of wear, damage, or misalignment beneath your belts. Address any issues promptly to prevent costly breakdowns.

Environmental Impact: Consider the environmental impact of your cleaning and maintenance methods. Opt for eco-friendly solutions wherever possible to align with sustainability goals.

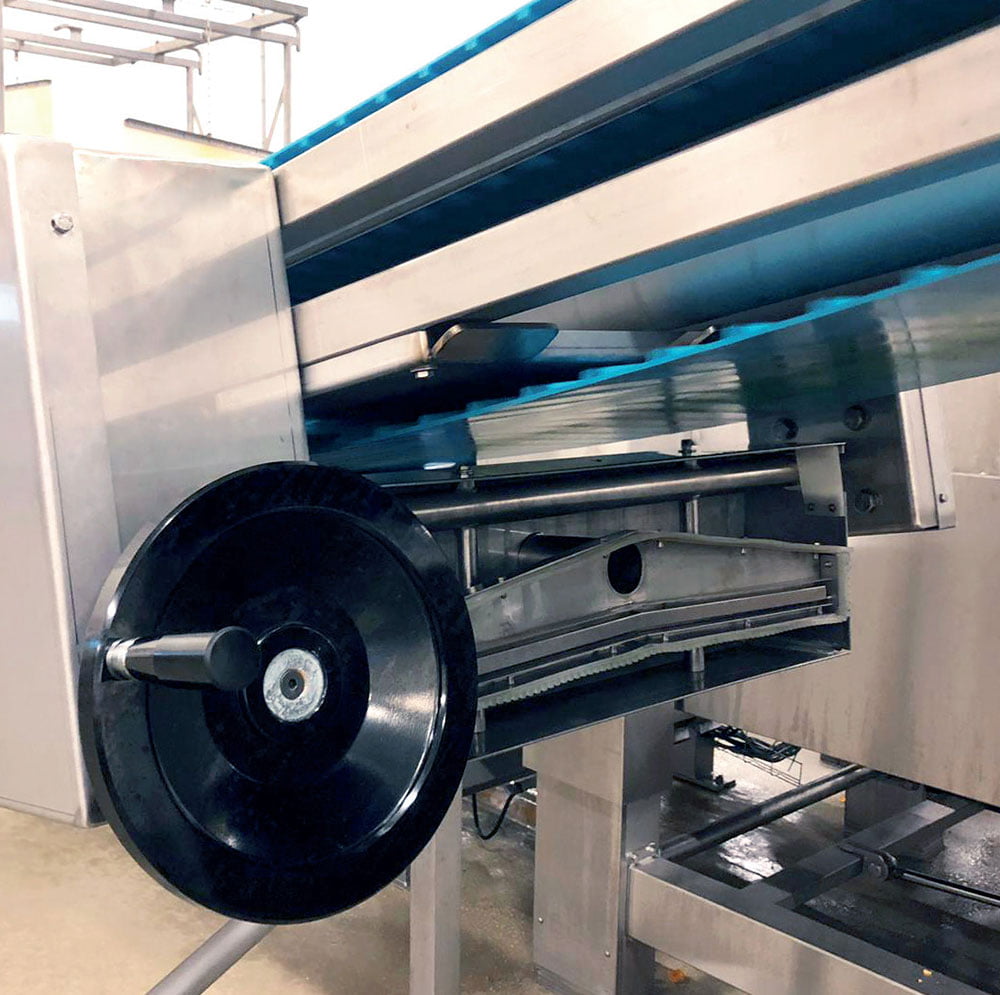

Designed for All Conveyor Belt Types: Meet Our Machines

To simplify cleaning and maintenance, a range of state-of-the-art machines is available. These heavy-duty machines are designed to efficiently and effectively clean beneath these conveyor systems, ensuring smooth and safe operations.

At ConveyorCleaning.com.au, we offer a comprehensive suite of conveyor cleaning solutions tailored to meet the unique needs of various industries and applications. Our cutting-edge machines are engineered for durability and high performance, helping you maintain the pristine condition of the undersides of your belts.

Explore our range of innovative cleaning machines – whether you operate in mining, manufacturing, food processing, or any other industry, we have the right equipment to keep your belts in top shape.

Visit ConveyorCleaning.com.au to discover how our solutions can elevate cleaning and maintenance to a new level of excellence. Experience the difference with equipment designed for all conveyor cleaning types and ensure the longevity and efficiency of your operations.

Maintaining Conveyor Belt Cleanliness for Longevity

Maintaining cleaning of the conveyor belts need not be daunting. With the right equipment, knowledge, and dedication to cleanliness, you can extend the lifespan of your conveyor system and enhance operational efficiency. Here are some tips to ensure that the underneath parts remain clean and long-lasting:

Proper Storage: When not in use, store belts in a clean and dry environment. Protect them from harsh weather conditions and direct sunlight.

Scheduled Inspections: Conduct regular inspections to identify signs of wear, damage, or misalignment beneath your belts. Address these issues promptly to prevent further damage.

Tension Maintenance: Ensure that your belts are correctly tensioned to prevent slippage and excessive wear.

Appropriate Cleaning Solutions: Choose cleaning machines/equipment, agents and/or disinfectants that are safe for the belt materials.

Staff Training: Train your staff in proper cleaning and maintenance procedures, including the safe operation of cleaning equipment.

By following these guidelines and investing in quality cleaning equipment, you can significantly extend the life span and reduce maintenance costs.

Demystifying What Lies Under a Conveyor Belt

For those curious about the inner workings of a conveyor system, you might wonder, “What lies underneath?” The answer varies depending on the specific type and design of the conveyor, but

generally, a few key components are situated beneath the surface:

1. Rollers and Idlers

These support the belt and ensure smooth movement along the conveyor’s path.

2. Belt Cleaner

As discussed earlier, belt cleaners are crucial for removing material buildup and ensuring cleanliness beneath the belt.

3. Tensioning System

This maintains proper belt tension, preventing slippage.

4. Drive Mechanism

Depending on the design, the drive mechanism may be located beneath the belt, powering its movement.

Conclusion

Cleaning underneath the bottom part of the conveyor belt is a fundamental aspect of ensuring the smooth and safe operation of industrial and manufacturing processes. Neglecting this critical task can lead to reduced efficiency, contamination risks, and safety hazards. With the right equipment, proper cleaning procedures, and a commitment to maintenance, you can extend the lifespan of your conveyor belts, ensuring they continue to serve as the reliable workhorses of your industrial or manufacturing operations.

Now, it’s time to take action and implement the best cleaning solutions for your specific needs. To explore cutting-edge equipment and expert guidance, visit ConveyorCleaning.com.au today. Elevate the maintenance to a new level of excellence and keep your operations running smoothly.