Conveyor belts play a pivotal role in various industries, enabling efficient transportation of goods and materials. However, the accumulation of debris, contaminants, and residues on these belts can lead to operational inefficiencies and hygiene concerns. To address these challenges, the innovative approach of automated steam systems has emerged as a transformative solution, offering benefits across a wide range of industries.

Automated Solution For Any Type of Belt

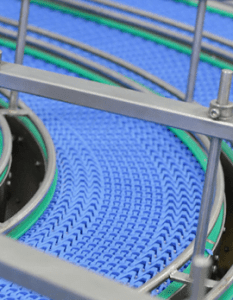

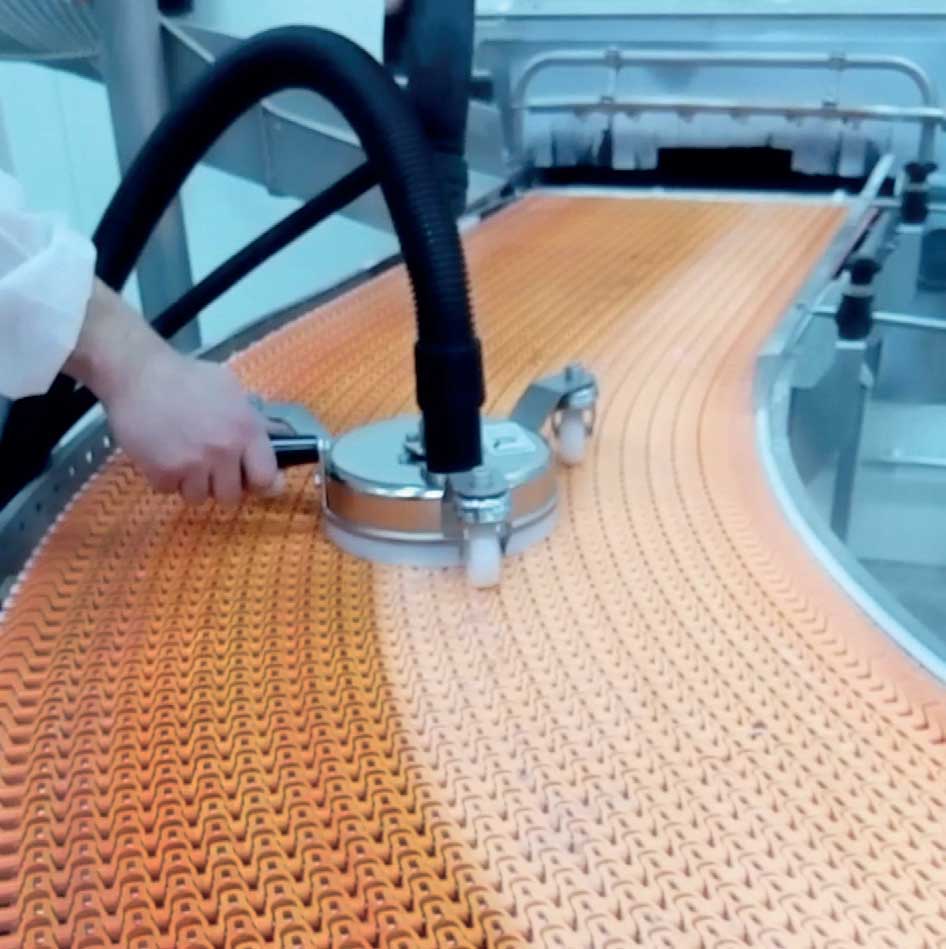

The conventional methods of belt cleaning often involve labour-intensive processes that may not effectively eliminate stubborn residues. The introduction of automated steam systems has revolutionised the way conveyor belts are maintained. These systems are designed to cater to various types of belts, including modular belts commonly used in industries like food processing.

Benefits of Using Dry Steam Belt Clean-In-Place

Steam cleaning involves the use of superheated steam to dislodge and remove contaminants from conveyor belts without the need for excessive water or chemicals. This method offers several notable benefits:

- Efficient Cleaning: Steam vapour, when applied through specialised nozzles, penetrates into crevices and hard-to-reach areas, effectively loosening and removing even the most stubborn residues. The automated nature of the process ensures consistent and thorough cleaning across the entire length of the belt.

- Water Conservation: Unlike traditional cleaning methods that rely heavily on water, the steam vapour system minimises water usage. This is not only environmentally friendly but also reduces downtime associated with excessive moisture that may need to evaporate before resuming operations.

- Chemical-Free Cleaning: The use of steam vapour eliminates the need for harsh chemicals, promoting a safer and healthier work environment. This is particularly crucial in the food industry, where maintaining the highest standards of hygiene is paramount.

- Reduced Labour and Maintenance Costs: Automated clean-in-place system significantly reduces the need for manual labour. Moreover, the automated systems are designed for durability and longevity, resulting in reduced maintenance costs over time.

- Enhanced Food Safety: In the food manufacturing industry, maintaining cleanliness is non-negotiable. High-temperature steam effectively sanitises the belts, minimising the risk of cross-contamination and ensuring compliance with stringent food safety regulations.

- Versatility and Adaptability: The modular design of many conveyor cleaning systems allows for easy integration into existing setups. This adaptability ensures that various industries can implement automated steam vapour without major disruptions to their operations.

Incorporating Automated Belt Cleaning Solutions

The automated conveyor belt cleaning approach typically consists of advanced technology components, such as conveyor belt cleaners with specially designed steam nozzles. These nozzles emit a controlled amount of steam at high temperatures, effectively dissolving and removing contaminants. Additionally, some systems incorporate adjustable cleaner blades that ensure optimal contact with the belt surface, enhancing the cleaning process.

Conclusion

In the realm of conveyor belt maintenance, the transition to automated steam vapour cleaning signifies a remarkable leap forward. The combination of efficiency, sustainability, and hygiene makes this method a game-changer for industries seeking optimal conveyor belt cleanliness. As the manufacturing

the landscape continues to evolve, embracing such cutting-edge solutions not only enhances operational efficiency but also underscores a commitment to environmental responsibility and product quality.